NorpA

Established

Hello,

I'm trying to repair my Iskra and in particular its well known film counter mechanism. As you probably know this system tries to avoid a double exposure and in the same time to rewind the counter to 0 when the back is opened in order to extract the used film.

With my Iskra I'm encountering these problems:

1. It's always possible to push the shutter button (double exposure lever doesn't work properly),

2. the rewind system stops to 1

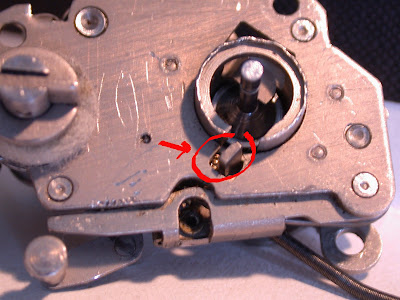

As far as I could see, the idea to prevent the double exposure is done by this lever:

1. here, the lever is out of the way, so the release button can be pressed

2. DEP (double exposure prevention) lever doesn't allow to push the button.

I guess this rotation is done by the related spring, but I don't understand if it's placed correctly on my camera (I'm sure someone opened it).

Could you confirm me this position?

Problem n°2, I've already seen a page where this point is discussed.

I'm trying to repair my Iskra and in particular its well known film counter mechanism. As you probably know this system tries to avoid a double exposure and in the same time to rewind the counter to 0 when the back is opened in order to extract the used film.

With my Iskra I'm encountering these problems:

1. It's always possible to push the shutter button (double exposure lever doesn't work properly),

2. the rewind system stops to 1

As far as I could see, the idea to prevent the double exposure is done by this lever:

1. here, the lever is out of the way, so the release button can be pressed

2. DEP (double exposure prevention) lever doesn't allow to push the button.

I guess this rotation is done by the related spring, but I don't understand if it's placed correctly on my camera (I'm sure someone opened it).

Could you confirm me this position?

Problem n°2, I've already seen a page where this point is discussed.

G

Guest

Guest

Why not phone Ken Ruth at Bald Mountain camera repairs, he is a very nice man and will talk your ears off. His site say's do not call other than on a few days of the week but I called him twice on Monday mornings and he answered. Your images can be emailed to give him an idea, I bet he will be a good help. He has a wealth of info, I talked about my Grand Fathers Newman and Guardia camera and he knew an incredible amount about it, even said he could service and repair it and it is a 1920's plate SLR camera.

James.

James.

NorpA

Established

Thanks jmpgino but I preferred to check my camera without involving a pro, otherwise, where is the pleasure to have an old and erratic FSU?

Yesterday, I had the opportunity to put my hands on this camera; now I'm here to share my experience.

First of all I want to say a big thank you Tõnu (Link) for his great online support and Hans (Link), who opened my eyes on Iskra's DEP.

Results:

I bought my Iskra in a flea market for few bucks, the idea wasn't to have a perfect camera but to have something to repair. Iskra had all the necessary prerequisites.

When I opened the topcover I immidiately noticed a mess with the film counter, his spring was completely winded and the gearwheel presented a couple of damaged teeth. In the same time everything looked in his position. So I started to remove everything, then clean, relube all pieces.

Unfortunately not only I had some missing teeth on the gearwheel, but even the transmission gear (n°3) presented a couple of damaged teeth. As result the film counter is not able to advance/rewind regularly. I'm quite sure that this situation is just a consequence due to the main problem.

Main problem:

My sprocket wheels (here) are no more correctly misaligned; that means I've no more the relative movement between them and the automatic feed once the shutter is pressed.

Long term project:

Actually I dont't know if with these assumptions it would be worth it to try fixing this mechanism or try the irreversible modification with the red window on the back.

Yesterday, I had the opportunity to put my hands on this camera; now I'm here to share my experience.

First of all I want to say a big thank you Tõnu (Link) for his great online support and Hans (Link), who opened my eyes on Iskra's DEP.

Results:

I bought my Iskra in a flea market for few bucks, the idea wasn't to have a perfect camera but to have something to repair. Iskra had all the necessary prerequisites.

When I opened the topcover I immidiately noticed a mess with the film counter, his spring was completely winded and the gearwheel presented a couple of damaged teeth. In the same time everything looked in his position. So I started to remove everything, then clean, relube all pieces.

Unfortunately not only I had some missing teeth on the gearwheel, but even the transmission gear (n°3) presented a couple of damaged teeth. As result the film counter is not able to advance/rewind regularly. I'm quite sure that this situation is just a consequence due to the main problem.

Main problem:

My sprocket wheels (here) are no more correctly misaligned; that means I've no more the relative movement between them and the automatic feed once the shutter is pressed.

Long term project:

Actually I dont't know if with these assumptions it would be worth it to try fixing this mechanism or try the irreversible modification with the red window on the back.

NorpA

Established

Ok, few words just to update this topic.

A couple of days ago, I found time and concentration to put my hands on my Iskra and its film counter. It was the third time I sat in front of this mechanism in order to understand how to solve its malfunction, so the disassemble procedure went smooth as butter for the first part: removed the top cover, separated the film counter from the rest of the camera.

Here the plate that hosts every gears and the shutter axis.

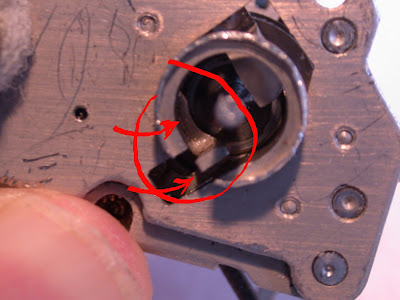

Whereas in this picture I took the still-beating heart of the system.

Next, I had to remove the shutter axis.

As discussed before, my attention was addressed to the double sprocket wheel, why was it stuck??

I have to admit that at this point I had to spend some time and unpolite words to understand how to remove the circular clip and the cone at the end of the shutter axis. In this procedure I received a great helping hand from Hans (link), because I was litterally without any idea on how I had to proceed. Gosh, it was easy: I thought the cone had a threaded axis, whereas it has only a looooooong axis that needed to be forced to slide out of the press button.

In this picture the release axis entirely exposed (from left to right): 1. press button, 2. clip to mantain the press button into the camera, 3. the ending of this axis with the cone used to avoid the double exposure.

Now, some pics to document why my camera wasn't able to work anymore.

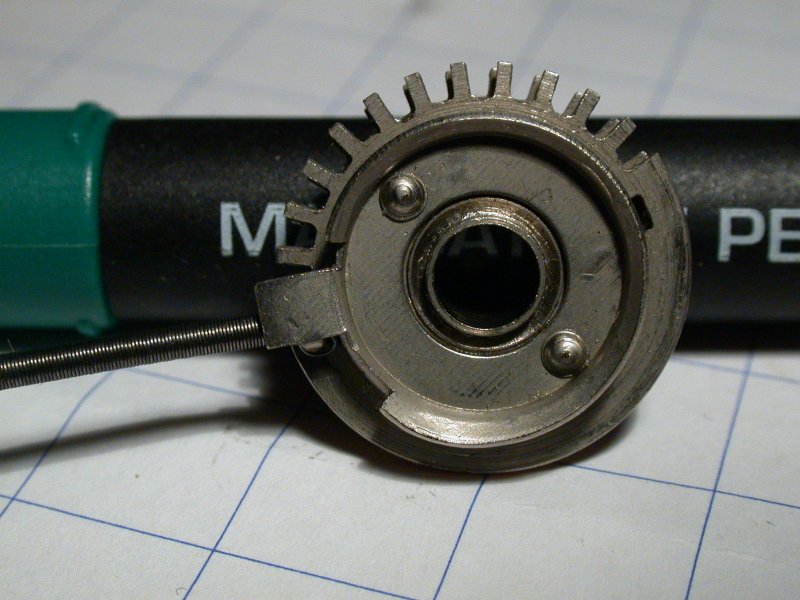

Here the double sprocket wheel is still stuck

Here the same part but in the correct position with its relative movement restored.

How did I restore this position? Actually, I was again without ideas, so I tryed with a desperate attempt... I placed my small screwdriver between the two weels and I (slightly) forced them... tadaaa! (I've been lucky).

So, finally I could reassemble my system with a little shrewdness... I placed the transmission gear on the release axis upside-down, in this way I misplaced the ruined teeth in an unused position.

So far I've just tryed the camera with a fake film, everything seems going well except a lazy returning in the starting position:

the long spring is able to rewind until the gear is wound at the 7th position, but it finds a small friction from this point on...

Ok, I have something more to investigate.

つづく

A couple of days ago, I found time and concentration to put my hands on my Iskra and its film counter. It was the third time I sat in front of this mechanism in order to understand how to solve its malfunction, so the disassemble procedure went smooth as butter for the first part: removed the top cover, separated the film counter from the rest of the camera.

Here the plate that hosts every gears and the shutter axis.

Whereas in this picture I took the still-beating heart of the system.

Next, I had to remove the shutter axis.

As discussed before, my attention was addressed to the double sprocket wheel, why was it stuck??

I have to admit that at this point I had to spend some time and unpolite words to understand how to remove the circular clip and the cone at the end of the shutter axis. In this procedure I received a great helping hand from Hans (link), because I was litterally without any idea on how I had to proceed. Gosh, it was easy: I thought the cone had a threaded axis, whereas it has only a looooooong axis that needed to be forced to slide out of the press button.

In this picture the release axis entirely exposed (from left to right): 1. press button, 2. clip to mantain the press button into the camera, 3. the ending of this axis with the cone used to avoid the double exposure.

Now, some pics to document why my camera wasn't able to work anymore.

Here the double sprocket wheel is still stuck

Here the same part but in the correct position with its relative movement restored.

How did I restore this position? Actually, I was again without ideas, so I tryed with a desperate attempt... I placed my small screwdriver between the two weels and I (slightly) forced them... tadaaa! (I've been lucky).

So, finally I could reassemble my system with a little shrewdness... I placed the transmission gear on the release axis upside-down, in this way I misplaced the ruined teeth in an unused position.

So far I've just tryed the camera with a fake film, everything seems going well except a lazy returning in the starting position:

the long spring is able to rewind until the gear is wound at the 7th position, but it finds a small friction from this point on...

Ok, I have something more to investigate.

つづく

graywolf

Well-known

Hard to tell from your photos, but it kind of looks like the 50 year old lube dried out and someone tried to force it, bending things slightly. These kinds of projects can be a lot of fun, if you do not let yourself become too frustrated.

I hope to have the capability of making small bits and pieces myself in another month or so. I bought a used mini lathe on eBay that has become a project in itself, luckily you can get parts for them. Unluckily, i had to spend the money I intended to spend on needed accessories on those parts. However, I figured out a long time back that things are always going to cost five times as much, and take five times as long as I expect, so I am not too upset (except about the fact that the seller lied about the condition of the lathe).

I hope to have the capability of making small bits and pieces myself in another month or so. I bought a used mini lathe on eBay that has become a project in itself, luckily you can get parts for them. Unluckily, i had to spend the money I intended to spend on needed accessories on those parts. However, I figured out a long time back that things are always going to cost five times as much, and take five times as long as I expect, so I am not too upset (except about the fact that the seller lied about the condition of the lathe).

R

rpinchbeck

Guest

Wow! This is awesome. I'm just coming to the completion of a Rolleicord and have an Iskra for my next project lined up. This information will be very helpful.

Cheers,

Russ Pinchbeck

Cheers,

Russ Pinchbeck

NorpA

Established

Thank you gentlemen,

your feedbacks are very appreciated.

R.B.I hope you have lots of fun, as I'm having, with this old gear.

PS. Here, just to complete the description, a picture that points out (green arrows) how my transmission gear has been damaged (please don't pay attention on the labels A/B they were referred to other things,): 1. a couple of missing teeth (completely worn out) 2. the tiny transmission axis with a folded tooth. In this last case I chose to cut the damaged tooth, maybe I'm wrong but I thought that it would have been better to have a missed tooth instead to a damaged one.

your feedbacks are very appreciated.

R.B.I hope you have lots of fun, as I'm having, with this old gear.

PS. Here, just to complete the description, a picture that points out (green arrows) how my transmission gear has been damaged (please don't pay attention on the labels A/B they were referred to other things,): 1. a couple of missing teeth (completely worn out) 2. the tiny transmission axis with a folded tooth. In this last case I chose to cut the damaged tooth, maybe I'm wrong but I thought that it would have been better to have a missed tooth instead to a damaged one.

Last edited:

t6un

Established

Bravo, you are a very patient repairman, and IMO the few remaining Iskras without the red window really deserve to stay that way!

About the damaged gear, it could be repaired by filing away part of the gear under the damaged teeth, soldering in a new pieces of brass and forming the new teeth with a file.

Hard soldering would be ideal of course but i have a hunch that here you could get away with the usual tin-lead alloy as well?

EDIT: this wouldn't work on the tiny transmission gear of course

About the damaged gear, it could be repaired by filing away part of the gear under the damaged teeth, soldering in a new pieces of brass and forming the new teeth with a file.

Hard soldering would be ideal of course but i have a hunch that here you could get away with the usual tin-lead alloy as well?

EDIT: this wouldn't work on the tiny transmission gear of course

Last edited:

Share: