KoNickon

Nick Merritt

I have just come into possession of a really pretty IIIg, from another RfF member. I had never held one before, and I like its features.

When the camera arrived, I noticed that the fast shutter speed dial was way out of alignment -- the dial appeared to be at least 1/4 rotation off from lining up with the correct speeds.

I figured that maybe the three grub screws securing the dial maybe were loose, or perhaps the dial had been removed and reinstalled hastily. So I loosened the screws, aligned it properly and tightened up the screws.

But the problem resurfaced immediately. Each release of the shutter caused the dial to drift off out of alignment -- no doubt because of the momentum from the spinning of the dial when the shutter is released, followed by sudden cessation of rotation.

Removing the dial entirely was a surprise -- there is only a very thin flange that the dial rests on, and the grub screws don't actually engage head on with the flange surface but rather against a beveled edge of the flange. If the screws' pointed ends were able to dig into the surface, there might be no drifting at all. Seems like a design flaw to me! But I've never heard of this problem before with this camera, or with any Barnack Leica, for that matter. Suggestions? Maybe the grub screws need to be slightly longer?

I should emphasize that the seller is willing to stand behind this, and it may require sending this off to the guy who CLA'd it last year to make it right. But before doing anything further, I wanted to see whether others had encountered the problem, and how they cured it. Thanks.

When the camera arrived, I noticed that the fast shutter speed dial was way out of alignment -- the dial appeared to be at least 1/4 rotation off from lining up with the correct speeds.

I figured that maybe the three grub screws securing the dial maybe were loose, or perhaps the dial had been removed and reinstalled hastily. So I loosened the screws, aligned it properly and tightened up the screws.

But the problem resurfaced immediately. Each release of the shutter caused the dial to drift off out of alignment -- no doubt because of the momentum from the spinning of the dial when the shutter is released, followed by sudden cessation of rotation.

Removing the dial entirely was a surprise -- there is only a very thin flange that the dial rests on, and the grub screws don't actually engage head on with the flange surface but rather against a beveled edge of the flange. If the screws' pointed ends were able to dig into the surface, there might be no drifting at all. Seems like a design flaw to me! But I've never heard of this problem before with this camera, or with any Barnack Leica, for that matter. Suggestions? Maybe the grub screws need to be slightly longer?

I should emphasize that the seller is willing to stand behind this, and it may require sending this off to the guy who CLA'd it last year to make it right. But before doing anything further, I wanted to see whether others had encountered the problem, and how they cured it. Thanks.

Vickko

Veteran

The shutter dial and the three grub screws might not be the problem.

The issue might be the round flange base, which is held on by one big slotted screw. That part might be loose.

And it if is, then it will move with every release of the shutter.

The issue might be the round flange base, which is held on by one big slotted screw. That part might be loose.

And it if is, then it will move with every release of the shutter.

KoNickon

Nick Merritt

Vick, thanks -- I'll check that again. This is the large screw facing up right in the middle of the flange base, right? I'm pretty sure it had no play, though I didn't go so far as to use a screwdriver to tighten it. Good suggestion; fingers crossed.

Vickko

Veteran

Yes, that is the screw, with a long slot, in the middle of the flange base.

It is also associated with the spring loaded pull-up of the shutter dial.

That spring loading may take up any play, but you will be able to tell if it is loose if you use a screwdriver.

It is also associated with the spring loaded pull-up of the shutter dial.

That spring loading may take up any play, but you will be able to tell if it is loose if you use a screwdriver.

KoNickon

Nick Merritt

Got it. Will crank that down tight and see what happens.

colyn

ישו משיח

Got it. Will crank that down tight and see what happens.

This is not the problem. If you over tighten it you'll shear it off. There is a screw that secures the speed plate to the main shutter drum shaft which has most likely sheared off. In other words the speed plate which the dial is secured to is drifting.. The only way to fix it is to have it repaired by a tech unless you are familiar with overhauling these models.

As for the grub screws not going directly into the flange this is normal and as long as the screws are properly tightened will not be an issue. The side gripping of this method give more secure gripping power..

KoNickon

Nick Merritt

Colyn, thanks for this; you may be correct since I just checked the screw Vick mentioned and it's perfectly tight. The cause you suggest is well beyond my capabilities to fix. But you mention the dial being secured to the speed plate; the only thing it is secured to is the flange directly below it, which as far as I can tell isn't drifting at all -- it returns to the exact same orientation (as indicated by that screw you warned about over tightening) each time I trip the shutter.

jarski

Veteran

am having same problem, though in my case it started slowly to surface year or two _after_ my IIIg was CLA'd (I was using the camera very irregularly, so it took a while). now its too late to complain about CLA anymore, so hope some answer appears here

colyn

ישו משיח

Colyn, thanks for this; you may be correct since I just checked the screw Vick mentioned and it's perfectly tight. The cause you suggest is well beyond my capabilities to fix. But you mention the dial being secured to the speed plate; the only thing it is secured to is the flange directly below it, which as far as I can tell isn't drifting at all -- it returns to the exact same orientation (as indicated by that screw you warned about over tightening) each time I trip the shutter.

I should clarify myself here. The dial is not hard secured to the speed plate. It is connected by way of a pin that drops into a hole on the speed plate. Each time you change shutter speeds you lift the dial and turn then it drops into a different hole. If the plate is drifting then the orientation of the dial will change.

KoNickon

Nick Merritt

But wouldn't the flange base drift as well? You may well be right in your diagnosis, but my pea brain isn't following. jarski's experience seems to be exactly mine -- reinforces my uneducated conclusion that the repairer doing the CLA in his and my case didn't reinstall the speed dial correctly. Hard to believe the screw would have gotten sheared off in both our cameras.

colyn

ישו משיח

But wouldn't the flange base drift as well? You may well be right in your diagnosis, but my pea brain isn't following. jarski's experience seems to be exactly mine -- reinforces my uneducated conclusion that the repairer doing the CLA in his and my case didn't reinstall the speed dial correctly. Hard to believe the screw would have gotten sheared off in both our cameras.

The flange which is also known as the disengaging lever is attached to the main shutter drum shaft by way of the top screw which is spring loaded. If this screw gets loose it will still work fine unless it works its way completely out. You'll then have a floating dial.. It will turn the closing curtain cam not the shutter drum. If this screw is in fact sheared it will change the orientation of the speed ring which in turn will cause the dial to be off since it is spring loaded to drop into a hole on the speed ring when changing shutter speeds.

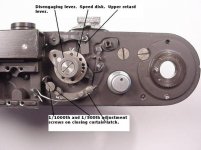

In the second image below the small diameter screw next to the speed disk is the screw I believe is your problem.. This will also affect the accuracy of the shutter speeds.

KoNickon

Nick Merritt

I think we're talking about two different flanges here. I have not removed the top cover of the camera, only the speed dial, so I don't see the speed plate assembly at all. The piece that's exposed when I remove the speed dial has a wide, thin flange to which the speed dial attaches with grub screws. It in turn is secured to -- I don't know what -- by means of a large recessed screw in the middle. Or is perhaps that piece with the large flange the top of the disengaging lever?

Are these pictures (thanks so much for attaching them, very helpful) of a IIIg? I have a IIIf also, and the speed dial for the IIIf appears to be secured differently. There are three holes in the knurling around the rim of the dial, but no grub screws visible at all, so I'm thinking it's a different assembly.

I really appreciate your help on this.

Are these pictures (thanks so much for attaching them, very helpful) of a IIIg? I have a IIIf also, and the speed dial for the IIIf appears to be secured differently. There are three holes in the knurling around the rim of the dial, but no grub screws visible at all, so I'm thinking it's a different assembly.

I really appreciate your help on this.

colyn

ישו משיח

I think we're talking about two different flanges here. I have not removed the top cover of the camera, only the speed dial, so I don't see the speed plate assembly at all. The piece that's exposed when I remove the speed dial has a wide, thin flange to which the speed dial attaches with grub screws. It in turn is secured to -- I don't know what -- by means of a large recessed screw in the middle. Or is perhaps that piece with the large flange the top of the disengaging lever?

Are these pictures (thanks so much for attaching them, very helpful) of a IIIg? I have a IIIf also, and the speed dial for the IIIf appears to be secured differently. There are three holes in the knurling around the rim of the dial, but no grub screws visible at all, so I'm thinking it's a different assembly.

I really appreciate your help on this.

These images represent the IIIc and IIIf but are also very simuliar to the iiig. In fact the parts between them are nearly identical.

Note the red arrow: That end is the flange where the dial attaches via the 3 grub screws. When you remove the dial you'll see that upper part of the disengaging lever. When you lift and turn the dial to change shutter speeds you also lift and turn the disengaging lever and place the pin (seen on the bottom of the disengaging lever) into a different hole on the speed plate. This in turn moves the closing curtain cam which then changes shutter speed by changing the distance from the main shutter drum.

KoNickon

Nick Merritt

Well, if the red arrow marks where the grub screws on the dial attach to the disengaging lever of the IIIc or IIIf, then the disengaging lever of those models is significantly different from that of the IIIg. As I've mentioned, there is a very noticeable flange, practically the same diameter as that of the dial itself, and that flange is much larger in diameter than the barrel of the disengaging lever. Sorry to be contradictory, but what I'm seeing looks a lot different from the top of the disengaging lever in your pictures.

colyn

ישו משיח

Well, if the red arrow marks where the grub screws on the dial attach to the disengaging lever of the IIIc or IIIf, then the disengaging lever of those models is significantly different from that of the IIIg. As I've mentioned, there is a very noticeable flange, practically the same diameter as that of the dial itself, and that flange is much larger in diameter than the barrel of the disengaging lever. Sorry to be contradictory, but what I'm seeing looks a lot different from the top of the disengaging lever in your pictures.

I agree. The IIIg does have a larger dial and flange than the IIIc/IIIf models however the mechanical workings are the same throughout the Barnack line.

You might try setting the shutter speed to a higher speed such as 100th or faster, remove the dial and make a mark on the flange and an alignment mark on the body with the shutter cocked. Advance and fire the shutter a number of times and see if the flange moves away from the mark. If it does then the problem is the screw that secures the speed ring to the drum shaft.

Since most camera repairmen don't have the proper tool to remove this screw during overhaul they end up damaging it which can cause stress and breakage. I bought one recently that was repaired by a local tech. He couldn't get the screw screwed completely in so he filed off the part still sticking out so he would be able to replace the disengaging lever which slips over this screw. I had to take it to a machinist and have it drilled out so I could replace it..

KoNickon

Nick Merritt

Colyn, that's a good idea and I'll give that a try -- that should definitely determine whether the issue is the screw that secures the speed ring to the shaft. I am away for the weekend but will check this when I get back.

So this screw requires special tools to install and remove? That may be a key factor in deciding whom to send the camera to. Would appreciate any recommendations (I'm thinking of the "usual suspects" but your thoughts would be good to hear -- by PM if you prefer.)

So this screw requires special tools to install and remove? That may be a key factor in deciding whom to send the camera to. Would appreciate any recommendations (I'm thinking of the "usual suspects" but your thoughts would be good to hear -- by PM if you prefer.)

colyn

ישו משיח

So this screw requires special tools to install and remove? That may be a key factor in deciding whom to send the camera to. Would appreciate any recommendations (I'm thinking of the "usual suspects" but your thoughts would be good to hear -- by PM if you prefer.)

It will require a special tool to do it right. The head of the screw is soft and will strip out easily and since pressure has to be applied the drum shaft can be bent or even broken off if you are using just a standard screw driver. You also have to have a puller to remove the speed disk which is pressed onto the shaft. Some non-factory train repairmen use a small prybar to do this but it warps the speed disk.

My personal preference is DAG or Sherry. They are both factory trained and will have the proper tools to do the job right..

mikemc_photo

Established

All these series cameras were the bread and butter of the old National Camera (NatCam) and were taught from top to bottom in order to graduate, You had a major test on these, and one of the bigger issues were the shutter springs inside of the rollers...when the springs stretched due to wear and over tensioning this problem would occur. You can solve this, by a careful tensioning and retensioning, done slowly...not with a torque driver, but rather counting turns on the worm gears.This is assuming that the drum bearing and shaft are not nicked or damaged.

If you have access to a slit width checker, you will see this at any of the slit speeds 1/100 and faster if the FIRST curtain runs erratic,your rollers are the problem

DAG should be able to do this repair, I have not done any of these for years, but I did pull out the IIIf last week for grins, and she still sounds good...I will need to shoot a roll soon.

If you have access to a slit width checker, you will see this at any of the slit speeds 1/100 and faster if the FIRST curtain runs erratic,your rollers are the problem

DAG should be able to do this repair, I have not done any of these for years, but I did pull out the IIIf last week for grins, and she still sounds good...I will need to shoot a roll soon.

KoNickon

Nick Merritt

Wow, totally not simple!

mikemc_photo

Established

No its not, and I suspect is one reason the III series prices stay high for good working bodies. Most old school repairmen can do most anything but roller rebuild on these, but salvage parts are the norm.

I find the best thing for these is regular use, and keeping the shutter released, with the lens cover on when not shooting

I find the best thing for these is regular use, and keeping the shutter released, with the lens cover on when not shooting

Share:

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.