johannielscom

Snorting silver salts

Recently I sold a camera with a round clip-on lens hood that had a rectangular front and the new owner commented that the lens hood was a real asset, he'd had not had one before with a previous camera. In particular with uncoated lenses (he said) the hood was almost mandatory.

This triggered two things with me: 1) Old prewar Leitz lenses (most notably the Elmar 50/3.5 but maybe others too) had a clip-on hood with rectangular front, now priceless and unaffordable if you can find one. 2) British photographer James Ravilious had masked his hoods (and most of the camera) with duct tape to create the rectangular hoods himself. The link points to a YouTube film of 30mins that has his wife show the gear he used.

I'm a dork when it comes to math so I'm asking here: Is there any way to calculate minimal dimensions of the hood and rectangular cut-out for a lens? I suppose one would need both angles of view at the biggest and smallest aperture to calculate this, but then what?

BTW, I'm asking for full-frame film Leica's not the M8 or other APS-C sized gear...

film Leica's not the M8 or other APS-C sized gear...

Thanks for any help!

This triggered two things with me: 1) Old prewar Leitz lenses (most notably the Elmar 50/3.5 but maybe others too) had a clip-on hood with rectangular front, now priceless and unaffordable if you can find one. 2) British photographer James Ravilious had masked his hoods (and most of the camera) with duct tape to create the rectangular hoods himself. The link points to a YouTube film of 30mins that has his wife show the gear he used.

I'm a dork when it comes to math so I'm asking here: Is there any way to calculate minimal dimensions of the hood and rectangular cut-out for a lens? I suppose one would need both angles of view at the biggest and smallest aperture to calculate this, but then what?

BTW, I'm asking for full-frame

Thanks for any help!

Last edited:

ferider

Veteran

Yes, Johan. Give me an example, and I show you how. I need the length of the lens (including the hood), too.

Does the following make sense ?

x = (l + 27.8mm - f) * 35mm / f

For the diameter of a round hood, you need to replace 35mm with the image diagonal.

Roland.

Does the following make sense ?

x = (l + 27.8mm - f) * 35mm / f

For the diameter of a round hood, you need to replace 35mm with the image diagonal.

Roland.

johannielscom

Snorting silver salts

that is great Roland, I think I can figure it out myself from this!

I have a FISON for my uncoated Elmar 50/3.5 that I want to tape up with gaffer tape to make sure it keeps out any stray light.

I have a FISON for my uncoated Elmar 50/3.5 that I want to tape up with gaffer tape to make sure it keeps out any stray light.

sanmich

Veteran

assume you have the front circle of the hood.

Aren't you looking at the 2:3 rectangle that is included in this circle?

Pythagoras should be your friend here:

Diagonal (diameter of the hood)^2=(2a)^2+(3a)^2

Aren't you looking at the 2:3 rectangle that is included in this circle?

Pythagoras should be your friend here:

Diagonal (diameter of the hood)^2=(2a)^2+(3a)^2

menos

Veteran

I am really interested in the outcome of this (with, without modified hood shots on a 5cm Elmar)!

I am just learning to love my coated 5cm and uncoated 3.5cm Elmar - playing with hods sounds like fun!

I am just learning to love my coated 5cm and uncoated 3.5cm Elmar - playing with hods sounds like fun!

mdarnton

Well-known

The easy way to do this is take the back door off your M Leica, put the base back on, and mount it on a tripod. Put on the hood and lens, open the shutter with a locking cable release, and then while looking at the middle of the back of th lens from one edge of the film gate, shove something in on the opposite side of the hood until you see it through the lens from the back edge. Move that thing (I use a fingertip) back a mm or two, and that's where the tape goes.

You could easily slide a card in from one side of the hood while looking through from the other side of the film gate, for instance.

No calculations needed, and you REALLY know. This is how I test whether a longer hood than is supposed to work will work: stop the lens down all the way and look in from the back very corner of the film gate and see if the f/22 hole sees light or hood. You'll see better at the smallest opening because it becomes a case of all or nothing, then check it wide open to make sure you don't see anything there, either.

You could easily slide a card in from one side of the hood while looking through from the other side of the film gate, for instance.

No calculations needed, and you REALLY know. This is how I test whether a longer hood than is supposed to work will work: stop the lens down all the way and look in from the back very corner of the film gate and see if the f/22 hole sees light or hood. You'll see better at the smallest opening because it becomes a case of all or nothing, then check it wide open to make sure you don't see anything there, either.

CrisR

Well-known

Has anyone tried 3D printing lens hoods of this type? I've had a lot of experience prototyping with a 3D printer and can model the hoods myself very easily if i'm given all the appropriate dimensions? It's even printable in black plastic.

I currently have the same style vented, circular hoods on most of my lenses (CV 35/1.4, CV 40/1.4, ZM 50/2) perhaps i should have a go at making one with the same bayonet fitment?

I currently have the same style vented, circular hoods on most of my lenses (CV 35/1.4, CV 40/1.4, ZM 50/2) perhaps i should have a go at making one with the same bayonet fitment?

CrisR

Well-known

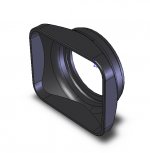

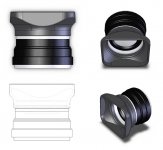

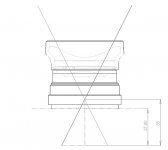

Well here's a quick, but accurate model of the CV 35/1.4 barrel, with the bayonet as a separate part. I didn't bother modeling the lens elements or any part recessed below the mount. I modeled it when at infinity, it's shortest length, but only one number needs to be changed to model it at it's longest as each barrel section is relative to the previous.

The original hood has sprung metal to hold it in place - as the 3D print would be all plastic, it'll be a friction fit instead and will only have one way of attaching it, instead of the 3x (rotated at 120 degrees) that the original hood does.

Now i can model, as a separate element, specific hoods for the 35, 40 and the Planar 50, each with their own ideal angle, but uniform mounting.

The original hood has sprung metal to hold it in place - as the 3D print would be all plastic, it'll be a friction fit instead and will only have one way of attaching it, instead of the 3x (rotated at 120 degrees) that the original hood does.

Now i can model, as a separate element, specific hoods for the 35, 40 and the Planar 50, each with their own ideal angle, but uniform mounting.

Attachments

CrisR

Well-known

Aaaand here's a test hood, just to get the basic form/shape down.

To give you an idea of cost, i could offer these for £35-40 ($55-65), maybe less, produced on-demand. The vented Planar hood costs £72 here in the UK

To give you an idea of cost, i could offer these for £35-40 ($55-65), maybe less, produced on-demand. The vented Planar hood costs £72 here in the UK

Attachments

Puggie

Established

How about Vac-forming a hood, much cheaper than 3d printing although not as pretty and you would still need to work out how to secure it to your lens. I seem to remember the square hood on my Pentax SMC Takumar 28mm f3.5 have a very nifty twist ring clamp to hold it in place, that might be relatively easy to replicate with a 3D printer, I think it used little cams and took about 1/8th of a turn to lock.

CrisR

Well-known

Vac-forming doesn't have the accuracy needed, nor the rigidity - plus it would take far more of my time and so the cost-saving wouldn't be there in the end. The printing costs aren't that bad at all really

CrisR

Well-known

Here's a new version based on the 35mm Summicron with the bayonet mount added. I'll need to check out some of the angles to make sure it doesn't cause problems on full frame, but then i'll have one made for my own testing.

Now i've had time to work on it, this version could sell for £25-30 ($40-48) as it uses less material

Now i've had time to work on it, this version could sell for £25-30 ($40-48) as it uses less material

Attachments

Dralowid

Michael

OK so I may be a bit slow but how do you use a rectangular hood on a 50mm 3.5 Elmar (or similar) where the whole lens rotates?

BTW, if anyone is interested, in the attic I have a box of 10 (?) unused FSU hoods that are rectangular...can't remember the fitting size...all in their original packaging, brown cardboard etc etc.............

BTW, if anyone is interested, in the attic I have a box of 10 (?) unused FSU hoods that are rectangular...can't remember the fitting size...all in their original packaging, brown cardboard etc etc.............

Godfrey

somewhat colored

OK so I may be a bit slow but how do you use a rectangular hood on a 50mm 3.5 Elmar (or similar) where the whole lens rotates?...

I wouldn't bother ... just stick with a round hood. Too much work otherwise.

CrisR

Well-known

CrisR

Well-known

The test prototype has been ordered - photos once it arrives!

CrisR

Well-known

useless generation

Established

Looks awesome

CrisR

Well-known

Thanks

It's a nice tight fit, holds firmly on the bayonet, build feels sturdy with a tiny bit of flex.

I didn't quite make the holes for the 3 tabs to slot into wide enough, it was off by 1mm, so i trimmed the proto the fit it and have updated the design too, so it's no problem now.

There's a bit of viewfinder blockage, as you'd expect, but only about 5-10%, so i've also done a version with a cutout in the corner for those that might want one.

I'll get better photos up soon, as well as pricing on both versions for those who want one themselves

It's a nice tight fit, holds firmly on the bayonet, build feels sturdy with a tiny bit of flex.

I didn't quite make the holes for the 3 tabs to slot into wide enough, it was off by 1mm, so i trimmed the proto the fit it and have updated the design too, so it's no problem now.

There's a bit of viewfinder blockage, as you'd expect, but only about 5-10%, so i've also done a version with a cutout in the corner for those that might want one.

I'll get better photos up soon, as well as pricing on both versions for those who want one themselves

sol33

Established

This is impressive and the results look great. Thanks for sharing this.

PS: I am clueless when it comes to these things, but would it be possible to use molding to make even cheaper hoods? (like described here: http://lcamtuf.coredump.cx/gcnc/)

PS: I am clueless when it comes to these things, but would it be possible to use molding to make even cheaper hoods? (like described here: http://lcamtuf.coredump.cx/gcnc/)

Share:

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.