HuubL

hunter-gatherer

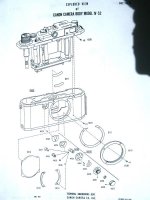

After gathering some info on its innards, yesterday I cleaned and lubricated my Contax IIa and I'm very happy with the results! The slow speeds run beautifully and everything works just silky smooth. This strengthened my confidence that I should also be able to fix the slow speeds on my Canon IVSb. However, before I start unscrewing it would be nice to have a general idea of where to start and what to expect... Anybody knows a link to a IVSb repair manual??