comp_wiz101

Compulsive Tinkerer

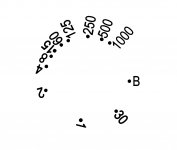

After a bit of work, I have created an image which, properly treated, can be used to replace the silkscreening on the Zorki 4/4K shutter speed dial. I suppose you could print it on transparancy, or paper with a protective layer of packing tape (as I have).

The image for printing should be printed at 1200 DPI in order to make sure it is life-sized. If you have a colour printer, you should use a simple "Paint" program to colour the speeds 1 - 1/30 in red.

The image for printing should be printed at 1200 DPI in order to make sure it is life-sized. If you have a colour printer, you should use a simple "Paint" program to colour the speeds 1 - 1/30 in red.