dcshooter

Member

Hey everyone,

I've managed to acquire a sample of this lens which is in great condition except for one problem: major delamination in both cemented doublets.

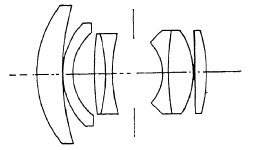

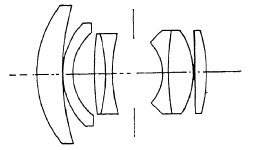

Here's a lens diagram for reference:

I've managed to extract the rear doublet and separate/recement it, but the front one is giving me a huge amount of trouble.

I've managed to remove the front two elements and am confronted with this:

That sure as heck looks like a small black retaining ring on the front, but I've had zero success removing it with heat/solvents/various rubber tools, etc. Unlike every other retaining ring in the lens, it doesn't have spanner notches.

Looking at it from behind, it looks like this. No obvious retaining rings on the back either. It looks to be all one machined brass piece.

I've managed to find the following page where a Chinese repairer seems to have managed to take this group out:

http://lens-cla.blogspot.com/2014/04/voigtlander-septon-50mm-f20-lens-group.html

Here's his picture of the removed doublet:

I've tried contacting this guy (in English) with no success, and running the page through Google translate seems to reveal only a general description of disassembling the lens.

So, has anyone here managed to similarly disassemble this lens? If so, do you have any tips/tricks as to how to get this dang thing apart?

Thanks!

I've managed to acquire a sample of this lens which is in great condition except for one problem: major delamination in both cemented doublets.

Here's a lens diagram for reference:

I've managed to extract the rear doublet and separate/recement it, but the front one is giving me a huge amount of trouble.

I've managed to remove the front two elements and am confronted with this:

That sure as heck looks like a small black retaining ring on the front, but I've had zero success removing it with heat/solvents/various rubber tools, etc. Unlike every other retaining ring in the lens, it doesn't have spanner notches.

Looking at it from behind, it looks like this. No obvious retaining rings on the back either. It looks to be all one machined brass piece.

I've managed to find the following page where a Chinese repairer seems to have managed to take this group out:

http://lens-cla.blogspot.com/2014/04/voigtlander-septon-50mm-f20-lens-group.html

Here's his picture of the removed doublet:

I've tried contacting this guy (in English) with no success, and running the page through Google translate seems to reveal only a general description of disassembling the lens.

So, has anyone here managed to similarly disassemble this lens? If so, do you have any tips/tricks as to how to get this dang thing apart?

Thanks!