ChrisN

Striving

In this thread I opened a discussion about the use of highly-diluted developers, which lead to a mechanical agitation processor I've been working on. During that discussion several contributors made the point that continuous rotation in one direction was likely to produce "flow marks" adjacent to the sprockets, caused by too-regular flows of developer in that area leading to uneven development.

Over several tests I found that was often true to varying degrees depending on time and developer concentration. I tested with agitation in two configurations: one with the tank rotated around the centre of the cylinder (as with Jobo rotary processor), and a second with the tank tumbled end-over-end (as with normal inversion agitation).

These tests were all made with continuous agitation in one direction at 4 rpm, as this was the simplest to implement.

Even with continuous agitation I did find a couple of interesting variations that showed some promise. The first of these was to modify a Paterson spool to allow it to slide freely on the centre column. The idea was that if the spool was free to move as the tank slowly tumbled end-over-end, more random flows of developer might be achieved. To some extent this worked but minor edge marks were still apparent. A second approach was to minimise flow volume and velocity by filling 95% of the volume of the tank with developer, using a small 1-reel tank. The Paterson 1-reel tank was filled with 510ml of water and 4ml of LC29 developer. A roll of PAN-F (50 iso) was developed for 60 minutes at 20c with continuous tumble agitation at 4rpm, and showed good contrast and even development.

I eventually concluded that I needed to find a way to either reverse the direction of rotation (as with Jobo) or with tumble agitation find a way to produce intermittent agitation more like the conventional process.

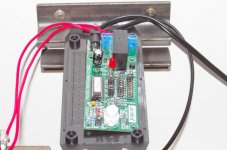

That lead me to investigate simple timers. I have no skills in electronics although I can manage a soldering iron and understand basic DC circuits. In Australia a company called Jaycar sells electrical and electronic components and kits: I found one of their kits that looked like it would do the job, offering two cycling switching states and the ability to set varying times to each. One problem is that the 12v DC motor that drives my device needs to be allowed to come to a complete stop (1 to 2 seconds) before reverse polarity current is applied to reverse the direction of rotation. I therefore needed a circuit that would allow me to run the motor in one direction, then stop for two seconds, then run it in the opposite direction, then stop for two seconds, then repeat. Using the Jaycar timer kit I would need three timers to achieve that. At $35 each that was starting to look expensive.

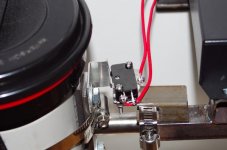

Some more thinking brought me to another solution, using intermittent tumble agitation. Using a single timer I could incorporate a micro-switch to stop the rotation of the motor when the tank was aligned in the vertical (normal) position. When the device is switched on the timer (in its “ON” state”) directly powers the DC motor for 20 seconds through one side of a SPDT relay switch. This tumbles the tank for about one and a half rotations. After the 20 seconds the timer flips to its “OFF” state which powers the DC motor though the other side of the SPDT relay switch and a normally-closed micro-switch. This “OFF” state is timed to run for 70 seconds. The tank has been tumbled for 20 seconds by the “ON” timer, then the “OFF” timer takes over and keeps it going for about 10 seconds until the micro-switch is opened when the tank is rotated to the point where the tank is vertical (normal). With the micro-switch open, power to the DC motor stops, rotation stops, and the timer ticks down its remaining 60 seconds with tank not moving. Then the whole process starts again.

So this gives me a gadget that will slowly agitate my tank for two rotations (about 30 seconds), then let it rest for one minute, then repeat the agitation, etc. I can adjust the timing of both the agitation and the resting states to give me longer agitation and/or longer resting states. This should be good for trialling semi-stand development regimes that require a little agitation every 15 or 30 minutes.

Testing so far with TRI-X developed for 20 minutes in ID-11 1+3 at 20c shows results that I can’t distinguish from the results I get with my normal development routine with manual agitation by hand (four inversions every minute).

Why bother? Well, I like the idea of semi-stand or similar processes that use a small amount of developer (call me cheap!). I’ve also enjoyed the challenge of making this gadget work and thinking about the mechanics of the film development process.

Photos to come.

Over several tests I found that was often true to varying degrees depending on time and developer concentration. I tested with agitation in two configurations: one with the tank rotated around the centre of the cylinder (as with Jobo rotary processor), and a second with the tank tumbled end-over-end (as with normal inversion agitation).

These tests were all made with continuous agitation in one direction at 4 rpm, as this was the simplest to implement.

Even with continuous agitation I did find a couple of interesting variations that showed some promise. The first of these was to modify a Paterson spool to allow it to slide freely on the centre column. The idea was that if the spool was free to move as the tank slowly tumbled end-over-end, more random flows of developer might be achieved. To some extent this worked but minor edge marks were still apparent. A second approach was to minimise flow volume and velocity by filling 95% of the volume of the tank with developer, using a small 1-reel tank. The Paterson 1-reel tank was filled with 510ml of water and 4ml of LC29 developer. A roll of PAN-F (50 iso) was developed for 60 minutes at 20c with continuous tumble agitation at 4rpm, and showed good contrast and even development.

I eventually concluded that I needed to find a way to either reverse the direction of rotation (as with Jobo) or with tumble agitation find a way to produce intermittent agitation more like the conventional process.

That lead me to investigate simple timers. I have no skills in electronics although I can manage a soldering iron and understand basic DC circuits. In Australia a company called Jaycar sells electrical and electronic components and kits: I found one of their kits that looked like it would do the job, offering two cycling switching states and the ability to set varying times to each. One problem is that the 12v DC motor that drives my device needs to be allowed to come to a complete stop (1 to 2 seconds) before reverse polarity current is applied to reverse the direction of rotation. I therefore needed a circuit that would allow me to run the motor in one direction, then stop for two seconds, then run it in the opposite direction, then stop for two seconds, then repeat. Using the Jaycar timer kit I would need three timers to achieve that. At $35 each that was starting to look expensive.

Some more thinking brought me to another solution, using intermittent tumble agitation. Using a single timer I could incorporate a micro-switch to stop the rotation of the motor when the tank was aligned in the vertical (normal) position. When the device is switched on the timer (in its “ON” state”) directly powers the DC motor for 20 seconds through one side of a SPDT relay switch. This tumbles the tank for about one and a half rotations. After the 20 seconds the timer flips to its “OFF” state which powers the DC motor though the other side of the SPDT relay switch and a normally-closed micro-switch. This “OFF” state is timed to run for 70 seconds. The tank has been tumbled for 20 seconds by the “ON” timer, then the “OFF” timer takes over and keeps it going for about 10 seconds until the micro-switch is opened when the tank is rotated to the point where the tank is vertical (normal). With the micro-switch open, power to the DC motor stops, rotation stops, and the timer ticks down its remaining 60 seconds with tank not moving. Then the whole process starts again.

So this gives me a gadget that will slowly agitate my tank for two rotations (about 30 seconds), then let it rest for one minute, then repeat the agitation, etc. I can adjust the timing of both the agitation and the resting states to give me longer agitation and/or longer resting states. This should be good for trialling semi-stand development regimes that require a little agitation every 15 or 30 minutes.

Testing so far with TRI-X developed for 20 minutes in ID-11 1+3 at 20c shows results that I can’t distinguish from the results I get with my normal development routine with manual agitation by hand (four inversions every minute).

Why bother? Well, I like the idea of semi-stand or similar processes that use a small amount of developer (call me cheap!). I’ve also enjoyed the challenge of making this gadget work and thinking about the mechanics of the film development process.

Photos to come.

Attachments

Last edited: