shawn

Veteran

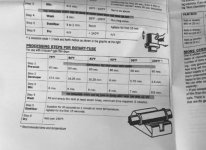

I built a C41 tempering bath out of a Finnex 300w aquarium heater. Stock the controller won't get high enough for C41. To modify the heater controller one resistor needs to be changed to alter the signal from the temperature sensor. Now if it is set to "90 degrees" the controller keeps the water temp at a very steady 104 degrees.

I just fill the tub with hot water, plug the heater in and let my chemicals heat up. As the water cools down the heater will maintain 104 degrees very well. By the time I am done with any B&W film the chemicals are ready to go for color. Just went through 5 hours of film processing and never had to touch the chemical temperature at all. I had a small pump to circulate the water but it wasn't working today and turns out it wasn't needed anyway.

Unfortunately, this mod prevents the heater from turning down enough for B&W. I find it unneeded for B&W anyway as I use one shot HC110 which is easy to get at the right temperature.

Shawn

I just fill the tub with hot water, plug the heater in and let my chemicals heat up. As the water cools down the heater will maintain 104 degrees very well. By the time I am done with any B&W film the chemicals are ready to go for color. Just went through 5 hours of film processing and never had to touch the chemical temperature at all. I had a small pump to circulate the water but it wasn't working today and turns out it wasn't needed anyway.

Unfortunately, this mod prevents the heater from turning down enough for B&W. I find it unneeded for B&W anyway as I use one shot HC110 which is easy to get at the right temperature.

Shawn