You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sepia toning

- Thread starter shadowfox

- Start date

- Latest activity Latest activity:

- Replies 13

- Views 3K

Alpacaman

keen bean

Thanks for this! I must try it some time now.

shadowfox

Darkroom printing lives

There has to be more than one person who are still interested in traditional way of toning 🙂

sepiareverb

genius and moron

Good overview. I've always numbered trays in the order I use them- niggling point I know.

Have you experimented with how developer effects final color?

I also like to use this kind of toner with a very brief bleach to get a split tone effect. Pulling from the bleach when highlights just vanish can produce some wonderful rich shadow tones.

Have you experimented with how developer effects final color?

I also like to use this kind of toner with a very brief bleach to get a split tone effect. Pulling from the bleach when highlights just vanish can produce some wonderful rich shadow tones.

bogelgelbo

RF student

There has to be more than one person who are still interested in traditional way of toning 🙂

I'm interested but it is hard to find any toning chemical here. I once read toning using tea or coffee, but I still don't know how.

shadowfox

Darkroom printing lives

Have you experimented with how developer effects final color?

I have not experimented with different developer as far as warm/cold. But I have seen drastic differences based on which paper "base color."

Adox MCP312 tones beautifully, btw, it looks almost like Kallitype or Paladium print.

shadowfox

Darkroom printing lives

I'm interested but it is hard to find any toning chemical here. I once read toning using tea or coffee, but I still don't know how.

Where is "here" ?

If you can find a lab or chemist in your town or city who is willing to mix some chemicals for you (for a price, unless he's your uncle 🙂 ), the formula for sepia toner and bleach are available even online. Just do some research on it.

Using tea/coffee, you stain the paper base. It's a form of toning, but it won't prolong the life of the print because it does nothing to the silver.

ZorkiKat

ЗоркийК&

- Local time

- 11:14 PM

- Joined

- Jan 26, 2006

- Messages

- 2,070

Tea, coffee, or any brown dye will stain the highlights and leave the blacks and greys as they are. Toning converts the image density areas to brown or whatever colour the chemical toner will impart on the original silver densities.

Sepia toning really involves varied processes, and the 'brown' obtained really ranges from lilac-pink to purple brown to bitter chocolate. The bleach-and-tone processes usually yields yellowish browns, and the actual shade itself depends on the paper emulsion type and on the procedure used. Partial bleaching, pre-toning (sulfide toner first then bleach), and bleach/tone/bleach methods are amongst those used to get variable shades of brown. Duotones (black + brown) can also be achieved.

My favourite method is the Hot-Alum method- a single bath toning system which involves an alum thiosulphate bath with a bit of silver thrown in. No bleaching needed, and the prints don't even have to be thoroughly washed prior to toning. This single-step toning method though needs to be heated to 50 deg C to work. The browns it makes are more red than yellow.

Sepia toning really involves varied processes, and the 'brown' obtained really ranges from lilac-pink to purple brown to bitter chocolate. The bleach-and-tone processes usually yields yellowish browns, and the actual shade itself depends on the paper emulsion type and on the procedure used. Partial bleaching, pre-toning (sulfide toner first then bleach), and bleach/tone/bleach methods are amongst those used to get variable shades of brown. Duotones (black + brown) can also be achieved.

My favourite method is the Hot-Alum method- a single bath toning system which involves an alum thiosulphate bath with a bit of silver thrown in. No bleaching needed, and the prints don't even have to be thoroughly washed prior to toning. This single-step toning method though needs to be heated to 50 deg C to work. The browns it makes are more red than yellow.

shadowfox

Darkroom printing lives

My favourite method is the Hot-Alum method- a single bath toning system which involves an alum thiosulphate bath with a bit of silver thrown in. No bleaching needed, and the prints don't even have to be thoroughly washed prior to toning. This single-step toning method though needs to be heated to 50 deg C to work. The browns it makes are more red than yellow.

That sounds interesting, do you happen to have a scan of the prints toned this way?

ZorkiKat

ЗоркийК&

- Local time

- 11:14 PM

- Joined

- Jan 26, 2006

- Messages

- 2,070

That sounds interesting, do you happen to have a scan of the prints toned this way?

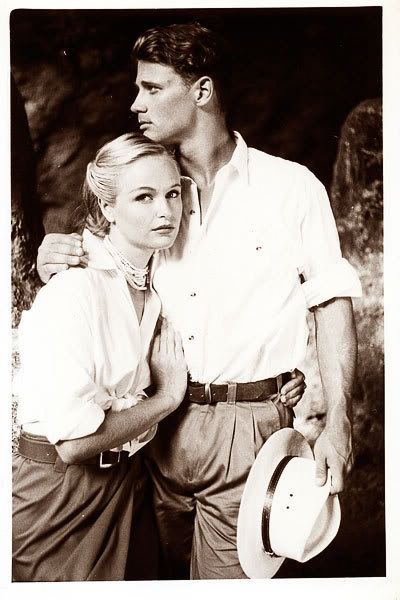

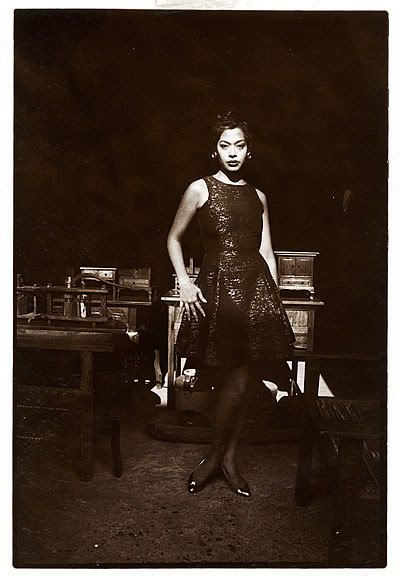

Here are two, toned using the Hypo-Alum hot toning method. These are from about 20 years ago, printed on Chinese made Xiamen chlorobromide paper. The scan and web rendering don't quite show the nuances of the sepia tone:

The Hypo Alum process is quite simple.

The toner formula is practically a Fixer bath which has gone bad:

Sodium Thiosulphate (10 water)- 200 g

Potassium Alum - 40 g

Water QS to 1 litre.

Hot water (60deg C) is used to mix the two ingredients. It will cloud immediately and a sulphuric sludge will form. To season the toner, a bit of silver nitrate (0.5 g) is added. Or the silver reserve can be provided by tossing 3 to 4 sheets of undeveloped 8X10 paper into the brew. The presence of silver is needed to prevent the toner from eating away the silver print image.

The silver sludge must not be removed or filtered out.

To use, the solution is heated to about 50 deg C, and the prints are slid into it. Toning would take about 10 or more minutes. The prints to be toned need not be washed thoroughly since the toning bath is just like the fixing bath. A developing tray placed in a heated water bath will work for this purpose. I used to put enamel metal trays over a hot plate to do this.

Once the prints are toned, they are washed in running water. Wash the usual way needed for prints. The silver sludge that the print may take along can be wiped off. The print will have a hardened emulsion as well. The sulphur smell can be retained by the print, but this won't be of any consequence to its longevity.

The toning solution can be reused several times. From what I remember, it lasted longer than the ferricyanide bleach and sulphide toner types.

Both RC/PE coated and regular fibre papers can be toned in this bath. However, there are one or two types of paper which won't tone in this bath. All of these were Chinese made papers.

Last edited:

sepiareverb

genius and moron

Nice! I was more of a selenium fan, with moderate toning (just shy of turning grays to browns).

You might really love the very brief bleach & sepia tone method.

ZorkiKat

ЗоркийК&

- Local time

- 11:14 PM

- Joined

- Jan 26, 2006

- Messages

- 2,070

Nice! I was more of a selenium fan, with moderate toning (just shy of turning grays to browns).

I also like the effect. Hints of purple in the darkest greys. "Intensifies" the image though.

The bleach-and-tone sepia methods tend to lighten the image a bit, when used as is.

shadowfox

Darkroom printing lives

Wow! Very nice!

I have to keep this process in my notes.

You'd be interested that if you tone Fomatone MG (warm tone paper) in 1+20 Selenium, you'd get a dark chocolate tone similar to these. I didn't believe it until I tried it myself.

ZorkiKat

ЗоркийК&

- Local time

- 11:14 PM

- Joined

- Jan 26, 2006

- Messages

- 2,070

Wow! Very nice!

I have to keep this process in my notes.

You'd be interested that if you tone Fomatone MG (warm tone paper) in 1+20 Selenium, you'd get a dark chocolate tone similar to these. I didn't believe it until I tried it myself.

Thanks shadowfox. I think Ilford Warmtone also behaves similarly. In Kodak selenium toner, they made rather nice bitter choco-brown (reminded me of Hershey's dark chocolates! 🙂 ) tones.

Similar threads

- Replies

- 6

- Views

- 1K