Let me revamp this post to share my experience.

The Model 35 camera depicted here is the first of the Rangefinder models produced by Yashica.

This camera has a fixed lens integrated with a Copal MXV shutter. So a leaf shutter solution which I am used to have with folding cameras, and which assure a smooth and silent experience.

What really impressed me about this camera was the clever idea to integrate the shutter cocking indicator directly in the frame counter window. Only one word: elegant.

The arrow indicating the frame number turns red or white depending if the shutter is respectively cocked or not. Sweet.

As soon as I got this camera I noticed that the take-up spool was rotating in the opposite direction as expected.

Without further ado, the transport mechanism was completely impaired and the camera has been declared dead since I couldn't find any spare parts around.

This disclaimer just to say that what will follow didn't harm any camera.

It is more a gift, a scientific autopsy to better understand the mechanical secrets of this photographic specimen.

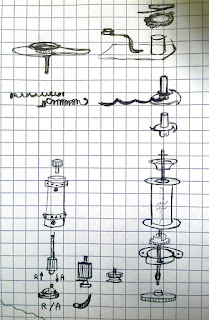

Step #1 disassembly the body

Here how the system looks when partially exposed

top (note the simple/simplistic mechanism to visualize the shutter state)

and bottom

Here the transport mechanism which is fully situated on the bottom part of the camera

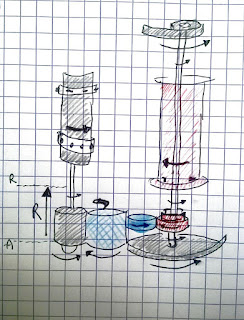

And here my notes to visualize and understand how the transport mechanism should work. (highlighting the different spins CW/CCW)

Two take away points here

1. this camera is based on a very thin principle: the wind lever engages the leaf shutter and control the transport mechanism. While the first movement is assured with a robust transmission chain, the latest is placed on the bottom of the camera, so we have a long and thin transmission axe with a threaded end tightening on a large gear. Jezz, this sounds like a single point of failure.

2. the film rewind release deal is quite bizarre. From the bottom of the camera we need to switch from A to R, now the transport mechanism is no more engaged and we can rewind the film in the cassette. Eventually we need to remember to bring back the rewind release deal from R to A before loading any other film.

Here the tricky part. The entire rewind mechanism is based on a spiral shim, when we turn the dial to R we move the spiral shim to its higher position, which will elevate the entire gear associate with the transport spool. In this moment the transport spool is not engaged and it can freely rotate allowing to rewind the film in the cassette. BUT!! I noticed that

EVERY time I move the dial from R to A, even if the spiral shim will move to its lower position, the transport gear will remain on the rewind position!

SUPER dangerous. As best practice I always suggest to manually rotate the transport spool as you want to rewind the film. This simple gesture will "remind" to the transport gear to move down and take the right position. Note you will hear a reassuring "click" and you will notice that you cannot rotate the transmission spool anymore in the rewind direction. This is what you want to assure a correct film transportation and even more important an healthy position fore the entire transmission gear chain.