Part 2

This part covers removing and servicing the slow-speed mechanism and assumes the top cover

is off.

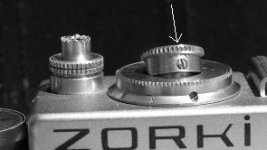

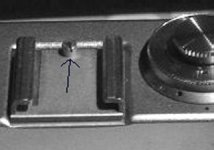

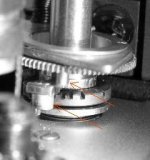

The mechanism sits over the speed-change mechanism and under the flash-synch switch (photo 17).

The switch is held in place by two screws on diagonal corners. Don't be fooled by the third

foot and hole - no screw there! Lift off the flash-synch switch carefully. While it's off,

clean the contact ring (photo 18) with a fibreglass or fine brass brush if you have one, otherwise

leave it alone. Make sure you return it to its former position if you rotate the moving part.

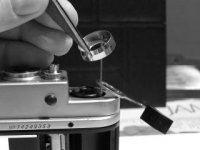

The slow-speed escapement is held by two screws (photo 19), one of which must be accessed

through one of the gears. This should line up if you cock the shutter and set 1/8 sec -

something not easily achieved at this stage! You can turn the largest gear slightly counter-

clockwise (as viewed from above) to achieve the same effect, and hold it there while undoing

the screw. Once the screws are out, lift the mechanism off, carefully manoevering it around

the shutter speed-selector parts. It will unwind too as soon as it's released, don't panic!

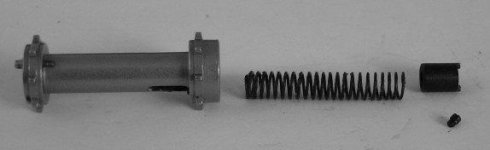

Dump the whole mechanism into cleaning fluid and let it soak a while. A small brush will help

to clean it if you have one. Let it dry fully before lubricating. Don't run the mechanism

unlubricated, it's quite delicate and you could damage it this way.

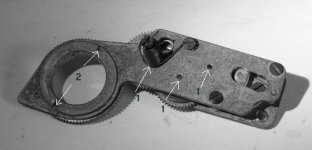

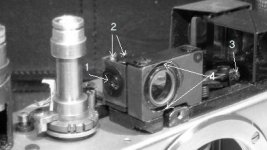

Using a very thin oil, lubricate the points shown (photos 20, points marked "1" & 2). Oil

VERY sparingly, using an oiler or a fine needle to get oil onto the spot required. There are

the six pinion pivots (three on top, three underneath) and the escapement pawl pivot (photo 22),

the wind-ratchet (photo 23) and the spring. Lightly, oil the smaller pinion (gear teeth!) on

each shaft too. Oil the teeth ofthe escapement pawl, again sparingly. Excess oil will only run

somewhere it doesn't belong and attract dirt.

Using a medium grade oil, oil the largest, ring-shaped gear where it runs against the

O-shaped plate (photo 20, points marked "2"). Turn the mechanism upside down and note

the pin on the ring-shaped large gear. Turn this gear clockwise about 3 turns to wind

the mechanism, then release it. See that the mechanism runs smoothly and unwinds compeletely.

It should come to rest in about the same place each time and not stick at any point. Try it

several times, partly to check this and partly to run the new oil around. Once you're happy,

set the mechanism aside somewhere clean (like a zip-loc plastic bag) while the other work

is done.

Now is a good time to deal with the RF/VF, whilst access is easier, then refit the slow-speed

escapement and flash-synchroniser, as detailed below, as the last jobs before refitting the

top cover. It is also a good idea to remove the shutter speed selector and grease the part it

sits on - undo the screw holding it, under which is a spring. Whilst at this stage, oil the

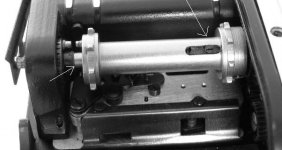

shutter drum shaft pivot: refer to photo 25 or 26, oil sparingly between the top plate and the

selector parts, where the shaft runs through the plate. Also, check the operation of the second

curtain release arm (photo 26A). To remove it, unhook the small spring, noting carefully how it

fits. Withdraw the shaft, clean and lubricate with thin oil then refit it and re-attach the

spring.

Re-fitting the slow-speed mechanism is the reverse of removal, with a couple of complications!

Read on.

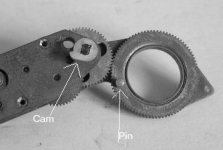

The ring-gear pin (photo 25) is engaged by the speed-selector at slow speeds. The slower the speed

the further it winds the mechanism. The speed-selector sits a little lower on 1/125 or faster,

so it misses the pin for higher speeds. At 1/60 it doesn't quite get to winding anything, but

for 1/15 or less it does. The little cam sticking out underneath the mechanism (photo 24) is what

blocks the shutter closing-curtain (via a tiny lever) until the delay time is up. Photo 25 shows

the shutter cocked at 1/125 with selector (left arrow) missing the pin (right arrow). Photo 26

shows the same situation for 1/2 sec, where the mechanism has been wound some way (same parts

arrowed).

Before re-fitting the mechanism, apply a TINY dab of silicone grease to the cam periphery. Be

aware that the cam operates a tiny lever and must sit beside it, so lower the mechanism

absolutely straight for the last few millimetres to avoid trapping the lever. The cam point

must not sit on top of the lever, hence the mechanism must be held as described below.

Before re-fitting the slow-speed mechanism, set the shutter speed to 1/1000 - do this by lifting

the speed-change and turning clockwise to the last notch. Don't worry about altering the speed

with the shutter un-cocked, at this point it doesn't matter (we'll check later that it's set

properly). Wind the escapement about one and one-half turns by means of the ring-shaped gear,

until the pin is adjacent to the triangular shaped projection. Holding in this position, re-fit

the mechanism, guiding it over the pin sticking up on the speed-change. Still holding the ring-gear,

refit the screws (very fiddly!), moving the gear slightly, if needed, to access the rear screw

that goes through a gear. Now release the mechanism, it should not unwind far. If it unwinds fully,

remove it and find out why! Once refitted Wind the mechanism a little, several times, it should

always unwind back to the exact same point (check the pin position, it should look like photo 25).

Now set the shutter speed to 1/60 by lifting the speed-selector and turning counter-clockwise.

Count your way through the notches to find 1/60. Cock the shutter by turning the film sprocket

in the direction of film travel (this is rough on the fingers!). Do this slowly and watch

the speed machanism as you wind. If anything fouls up, STOP and ascertain why, DON'T continue

to wind! When the shutter is cocked, the speed-selector should ALMOST contact the slow-speed

ring-gear pin. Fire the shutter and repeat with the speed set to 1/15 or less: this time the

pin should be engaged and the mechanism bewound up. Fire again and see if it sounds right.

Refer to photos 25 and 26 again to see how things should look.

Refit the flash-synchroniser once you're happy with the slow-speed escapement.