- Forums

- Rangefinder Forum

- Image Processing: Darkroom / Lightroom / Film

- Film / Developing / Chemistry

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

70mm Film FUN up ahead

- Thread starter Nokton48

- Start date

- Latest activity Latest activity:

- Replies 1K

- Views 188K

Stefan Wood

Established

Nokton48

Veteran

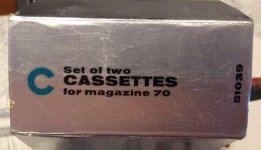

Here is the Hasselblad (but really, Kodak) 70mm cassettes I just received. Brand new, in box.

Nice. To find them new in the box is a bonus.

Sounds and looks like you are getting there. Best of Good Luck in your efforts! 🙂

Brett,

I dug out my wind knob back, and ran a dummy roll through, using the duct taped spool. The result is eight evenly spaced frames. I am pleased.

I gave it four winds of duct tape, figuring that would do it.

Next I am going to try this method with my old old Plaubel Makina backs. Those are notorious for uneven frame spacing. It should work!

-Dan

DSC05849 by Nokton48, on Flickr

Looks like you are good to go now! Well done. 🙂

I don't know much at all about the Makina backs, but with the Rollex, I suggest inspecting the area around the inside of the wind knob where it rotates inside the housing. I noticed a few small metal particles there and wasn't particularly happy about that. They most likely were lubricated when new but my example had been unused for many a long year and was quite dried out. I used a combination of a dab of moly grease and a speck of oil around the inner boss. Pull the knob out as if to remove or replace the film insert and make sure everything is clean and free of dust, too. After exercising the mechanism for a few minutes I wiped any excess lubricant off from around any exposed surfaces (there should not be much of that if you take care not to be too liberal). It winds a bit more smoothly now, and no longer wears, either.

It's easy to replace the light trap seals. There are about half a dozen screws visible in the plate around the film gate; removing these with the magazine inverted will see the plate detach leaving the small rollers sitting in their slots. These do not run on pins, they're a simple interference fit in slots between the body and the plate. After cleaning with lighter fluid and gently polishing the running surfaces with some Autosol metal polish and removing the residue of this, a speck of oil at each end (I used my usual Moebius 8030) will see them actually rotating in the slots as a film runs over them, as opposed to the film being dragged around them. The light trap seals are strips of velvet on a decently thick backing. It was quality stuff and I'd rather like to locate something like it, most shop velvet has a fabric backing far too thin for sealing purposes.

If the velvet strips in your Rollex aren't too badly worn you might be able to extend their usefulness, at least pending procurement of suitable replacements, as I believe these are no longer available from Linhof themselves? You could, potentially, do this by gently peeling them out of their slots and reversing the installation direction (if their condition suggests this may be beneficial, it may not) as well as shimming underneath them to compensate for the wear with paper or metal foil. It's easy to over adjust this, so a trial assembly to see how smoothly the dark slide inserts isn't a bad idea. The seals or their replacements can be re-glued into position after cleaning the slots with some contact adhesive.

My whole Linhof kit had been unused for many years. The case had rolls of Ilford FP3 and Ortho that expired in 1961! It was all still in pretty good condition, (you can see some photos of it and information about what I had to do to get it working, again, in this thread from last year) but dark slide of the Rollex had some corrosion present in a few places. Using it as it was wouldn't have done the light seals any good, so I spent a half an hour or so attacking it with Autosol and a cloth. A few pits remain but they don't matter, as long as the high points and rough edges are removed it will still work fine.

My seals were pretty flogged. The back had been stored with the slide in place and decades later they'd compressed enough to produce visible light leaks. (I think that generally, whenever one stores an unloaded film magazine it's not a bad idea to keep the slide removed, it is apart from anything else easy to tell at a glance that one is unloaded, this way.) My wife does a bit of knitting over the winter months and during a visit to one of her favourite wool stores I noticed small sheets of black felt sold for a few dollars. Of course I grabbed a few immediately as they can be so useful for various camera sealing applications. I cut some of this to size and replaced the original seals. It's not an ideal substitute--velvet would be better, because the felt is more susceptible to fibres being cut off when the slide is inserted. I'm fairly careful not to angle the slide when inserting it, and it has not been a problem to date but I'm still keeping a bit of an eye out for a similar material to the original seals.

Cheers,

Brett

Nokton48

Veteran

I have some fairly thick velvet ribbon that might work if it is wide enough.

I enjoy working with my hands and making unique unusual things work properly again.

It's FUN and then I have the pleasure of utilizing them.

All of this gear is from what I call "The Golden Age of Photography", back in the fifties and sixties.

I enjoy working with my hands and making unique unusual things work properly again.

It's FUN and then I have the pleasure of utilizing them.

All of this gear is from what I call "The Golden Age of Photography", back in the fifties and sixties.

Nokton48

Veteran

I have some fairly thick velvet ribbon that might work if it is wide enough.

I enjoy working with my hands and making unique unusual things work properly again.

It's FUN and then I have the pleasure of utilizing them.

All of this gear is from what I call "The Golden Age of Photography", back in the fifties and sixties.

I couldn't have put it any better myself.

Nokton48

Veteran

Here is the result of the duct taped spool, with one of my five or six 6x9cm Plaubel Makina backs. These are somewhat dodgy regarding frame spacing, so shoring this up, is HUGE for me. It's quite disapointing to have important frames overlap (especially when you are not expecting it!) The mechanism is rather primitive and archaic, as well as extremely unusual in design. But now it appears to be working beautifully so far.

Make a tick mark on the duct tape, with a sharpie marker, as you wrap it, so that you get the correct amount of tape on the spool. Easy to do.

Hurray! 🙂

DSC05861 (2) by Nokton48, on Flickr

DSC05861 (2) by Nokton48, on Flickr

Make a tick mark on the duct tape, with a sharpie marker, as you wrap it, so that you get the correct amount of tape on the spool. Easy to do.

Hurray! 🙂

DSC05861 (2) by Nokton48, on Flickr

DSC05861 (2) by Nokton48, on FlickrGlad it is working out for you. I haven't noticed any issues with film flatness or light leakage from not having the spool surface flush from end to end in the rolls I have shot. I think by the time you've wound the paper round one a few turns at the start of a roll, the film has that underneath it, and, once it's wrapped off at the end the paper will seal it off, anyway. I am, admittedly, always particular about keeping the paper tight as I fasten the end, because I have developed too many rolls for other people who were careless about this point and have seen the effects of not wrapping one correctly. But I think if someone had issues with light leaks from roll on a taped spool, they'd probably have them with a standard spool because proper technique should prevent fogging. In any case it's been no problem for me, to date.

Cheers

Brett

Cheers

Brett

Calzone

Gear Whore #1

I have been busy testing Rollie 400S, AKA Agfa Aviphot 200.

Further testing with Diafine 4+4, but with some piston action by using a 120 reel instead of a 220 reel did not improve the Bromide Drag artifacts in what should of been a nearly cloudless sunny blue sky. I did verify that the film speed that was optimum was only 50 ISO. Too bad because Diafine is reusable without any replenishment so the cost of developer is basically almost free.

I figured out that Rollie 400S is really a fine grain low speed film in reality. Diafine usually gives me a nice 2/3rds stop in film speed, except with Acros which I shoot at box speed (100 ISO). In this regard so far Rollie 400S is somewhat like Acros in being fine grained.

So I tried Rodinal 1:50 for 11 minutes. This time I got off of the MDC listed under Agfa Aviphot 200, but they rated the ISO at 200. In my testing I got the best tonality at 50 ISO under cloudy overcast conditions. Perhaps under sunny conditions I would rate 400S at 80 ISO for less contrast under brighter conditions.

BTW these negatives have a density optimized for wet printing and not scanning (slightly more exposure for denser negatives and more shadow detail).

The Rodinal 1:50 made some truely great negatives that display large format tonality, they have that Rodinal acutance and sharpness, and the compensating effect really brought out the mids. Very highly detailed and small grain.

I used my non daylight Nikor tank and a 15 foot reel to find out that I need 2 liters of solution to cover just one 15 foot 70mm reel. For two 15 footers a gallon of developer is required. Anyways Rodinal is cheap and affordable as a one shot, but the film speed is low. Looks like a magic combination using an Agfa developer on a rebranded Agfa film. The IQ is mucho high. Rodinal is mucho cheap if one is considering a one shot developer.

Next test will be trying to get a film speed over 100 ISO with perhaps Microphen. Dan's use of Acufine makes a lot of sense for two reasons: Acufine can be replenished; and Acufine is a strong active developer. Seems like Rollie 400S likes/requires a strong active developer. I think Jan and others are correct: Agfa Aviphot/Rollie 400S is really a 80-100 ISO film.

On another thread Jan reports of only being able to achieve 160 ISO with some German active push developer. If I'm able to get 125 or 160 ISO I will be mucho happy.

Cal

Further testing with Diafine 4+4, but with some piston action by using a 120 reel instead of a 220 reel did not improve the Bromide Drag artifacts in what should of been a nearly cloudless sunny blue sky. I did verify that the film speed that was optimum was only 50 ISO. Too bad because Diafine is reusable without any replenishment so the cost of developer is basically almost free.

I figured out that Rollie 400S is really a fine grain low speed film in reality. Diafine usually gives me a nice 2/3rds stop in film speed, except with Acros which I shoot at box speed (100 ISO). In this regard so far Rollie 400S is somewhat like Acros in being fine grained.

So I tried Rodinal 1:50 for 11 minutes. This time I got off of the MDC listed under Agfa Aviphot 200, but they rated the ISO at 200. In my testing I got the best tonality at 50 ISO under cloudy overcast conditions. Perhaps under sunny conditions I would rate 400S at 80 ISO for less contrast under brighter conditions.

BTW these negatives have a density optimized for wet printing and not scanning (slightly more exposure for denser negatives and more shadow detail).

The Rodinal 1:50 made some truely great negatives that display large format tonality, they have that Rodinal acutance and sharpness, and the compensating effect really brought out the mids. Very highly detailed and small grain.

I used my non daylight Nikor tank and a 15 foot reel to find out that I need 2 liters of solution to cover just one 15 foot 70mm reel. For two 15 footers a gallon of developer is required. Anyways Rodinal is cheap and affordable as a one shot, but the film speed is low. Looks like a magic combination using an Agfa developer on a rebranded Agfa film. The IQ is mucho high. Rodinal is mucho cheap if one is considering a one shot developer.

Next test will be trying to get a film speed over 100 ISO with perhaps Microphen. Dan's use of Acufine makes a lot of sense for two reasons: Acufine can be replenished; and Acufine is a strong active developer. Seems like Rollie 400S likes/requires a strong active developer. I think Jan and others are correct: Agfa Aviphot/Rollie 400S is really a 80-100 ISO film.

On another thread Jan reports of only being able to achieve 160 ISO with some German active push developer. If I'm able to get 125 or 160 ISO I will be mucho happy.

Cal

Calzone

Gear Whore #1

Dan and Brett,

I just bought another Linhof CINE. This one is a brown one with the circular Grafloc for 2x3. Only 99.00 EURO plus shipping. I don't know if it is a functioning unit because the description is in German, but I basically bought it for the 2x3 Grafloc mount.

I know that the 4x5 version and the 2x3 version have a modular design, meaning I can change the shells as well as the back mount. The idea here is to have two fully working and functional CINE's: one 645; and the other 6x7.

If the brown CINE from Germany is a functional unit, then I can have a discreet and third CINE dedicated to 4x5 by using the back plate that currently is in the 645 CINE after I convert it to 2x3.

BTW I have three Linhof's: two are Baby-Linhof's; and the third is an early 50's Tech IV that displays this wonderful patina of worn leather.

Cal

I just bought another Linhof CINE. This one is a brown one with the circular Grafloc for 2x3. Only 99.00 EURO plus shipping. I don't know if it is a functioning unit because the description is in German, but I basically bought it for the 2x3 Grafloc mount.

I know that the 4x5 version and the 2x3 version have a modular design, meaning I can change the shells as well as the back mount. The idea here is to have two fully working and functional CINE's: one 645; and the other 6x7.

If the brown CINE from Germany is a functional unit, then I can have a discreet and third CINE dedicated to 4x5 by using the back plate that currently is in the 645 CINE after I convert it to 2x3.

BTW I have three Linhof's: two are Baby-Linhof's; and the third is an early 50's Tech IV that displays this wonderful patina of worn leather.

Cal

Nokton48

Veteran

Dan and Brett,

I just bought another Linhof CINE. This one is a brown one with the circular Grafloc for 2x3. Only 99.00 EURO plus shipping. I don't know if it is a functioning unit because the description is in German, but I basically bought it for the 2x3 Grafloc mount.

I know that the 4x5 version and the 2x3 version have a modular design, meaning I can change the shells as well as the back mount. The idea here is to have two fully working and functional CINE's: one 645; and the other 6x7.

If the brown CINE from Germany is a functional unit, then I can have a discreet and third CINE dedicated to 4x5 by using the back plate that currently is in the 645 CINE after I convert it to 2x3.

BTW I have three Linhof's: two are Baby-Linhof's; and the third is an early 50's Tech IV that displays this wonderful patina of worn leather.

Cal

That's good information to know Cal. It sounds like even ratty looking Rollex backs are worth picking up at the right price, then, as inserts and mounting plates can still be put to use, as you've outlined above.

Cheers

Brett

Jake Mongey

Well-known

After having thoroughly depleted my savings, I have a functioning 500 EL 150 sonnar, 70mm dental reel, some E6 70mm stock and some plus X. Now all i need is an A70 and now most certainly a job.

Nokton48

Veteran

After having thoroughly depleted my savings, I have a functioning 500 EL 150 sonnar, 70mm dental reel, some E6 70mm stock and some plus X. Now all i need is an A70 and now most certainly a job.

Good Going Jake! 🙂 Cool that you were able to snag some 70mm Plus-X.

Calzone

Gear Whore #1

After having thoroughly depleted my savings, I have a functioning 500 EL 150 sonnar, 70mm dental reel, some E6 70mm stock and some plus X. Now all i need is an A70 and now most certainly a job.

Jake,

Even at $98.00 including VAT from MACO I figure $2.50 per 120 equiv. If I use $6.00 a roll for 135 the per shot cost of shooting 70mm Rollie 400S matches my 35 mm per shot cost for film (about $0.16 per shot). Just keep in mind I will have a 6x7 negative.

In your case 6x6 will have a lower film cost than 135, because you will have more frames. 32.5 inches equals a roll of 120, plus the possibility of bonus frames on longer lengths of film.

I think Rodinal is likely the cheapest one shot, especially if you use 1:50 dillution.

I see no reason not to shoot medium format like 135, because costs can be contained. What's not to like about the larger negative?

So the most cost effect approach with fresh film is Rollie 400S from MACO and Rodinal as the developer.

Over the long run you made a wise investment if B&W is what you do.

Cal

Calzone

Gear Whore #1

For the 70mm heads

Another cinema release in the format

Dunkirk : Chrostoper Nolan

Looks interesting

Rod,

I saw "Dunkirk" last night in 70mm. The story has only a few words and a few sentences.

A very visual film that definitely has an impact. I think the 70mm provided a heightened reality that was powerful.

Highly recommended. Cost me $19.50 for the ticket.

Cal

Nokton48

Veteran

Cal, I think you are really on to something, combining Rollei Developer and Rollei Film.

Look at these; They are absolutely lovely and I think you get more speed, too.

https://www.flickr.com/search/?text=rollei d74

The developer is Rollei D74, also known as A74. Highly compensating with 400S.

Now called Rollei RHS

D 74 A74 from the UK by Nokton48, on Flickr

D 74 A74 from the UK by Nokton48, on Flickr

What do you think? Haven't found it listed anywhere but a place in the UK.

Looks like they are putting their names on it

Rollei may have discontinued it, WHY???? It's wonderful stuff. I will keep looking.

Meanwhile there is Acufine to test when I have time (if I ever have time) 🙂

Look at these; They are absolutely lovely and I think you get more speed, too.

https://www.flickr.com/search/?text=rollei d74

The developer is Rollei D74, also known as A74. Highly compensating with 400S.

Here an example of Retro 400S E.I. 200 in D74 1+15. Retro 80S and Retro 400S are Agfa Gevaert aviation type films and they need a semi-compensating or a bit lower contrast working type developer. HC-110 is building up quickly a higher contrast.

It is a scan from a fiber print on Fomabrom Variant 111.

Now called Rollei RHS

D 74 A74 from the UK by Nokton48, on Flickr

D 74 A74 from the UK by Nokton48, on FlickrWhat do you think? Haven't found it listed anywhere but a place in the UK.

Looks like they are putting their names on it

Rollei may have discontinued it, WHY???? It's wonderful stuff. I will keep looking.

Meanwhile there is Acufine to test when I have time (if I ever have time) 🙂

Nokton48

Veteran

"Sneebot" is a Master Machinist, and fellow Plaubel Makiflex owner, I met him over on Flikr. He added the following comment to my wind knob back photo:

"I've had one of these apart. The 'cam follower' that tracks the 'frame spacing cam' is a horrible design. It easily wears away and causes spacing problems."

Just something to keep in mind.

DSC05849 by Nokton48, on Flickr

DSC05849 by Nokton48, on Flickr

"I've had one of these apart. The 'cam follower' that tracks the 'frame spacing cam' is a horrible design. It easily wears away and causes spacing problems."

Just something to keep in mind.

DSC05849 by Nokton48, on Flickr

DSC05849 by Nokton48, on FlickrCalzone

Gear Whore #1

Cal, I think you are really on to something, combining Rollei Developer and Rollei Film.

Look at these; They are absolutely lovely and I think you get more speed, too.

https://www.flickr.com/search/?text=rollei d74

The developer is Rollei D74, also known as A74. Highly compensating with 400S.

Now called Rollei RHS

D 74 A74 from the UK by Nokton48, on Flickr

What do you think? Haven't found it listed anywhere but a place in the UK.

Looks like they are putting their names on it

Rollei may have discontinued it, WHY???? It's wonderful stuff. I will keep looking.

Meanwhile there is Acufine to test when I have time (if I ever have time) 🙂

Dan,

I just want to shoot lots of film for no money. I figure a 100 feet of Rollie 400S in 70mm for about $98.00 (including VAT) really moderates film costs.

Rodinal is likely the cheapest one-shot, especially because you need a compensating effect that requires 1:50 dillution, but the only limitation is film speed being 50-80 ISO. Oh-well. BTW the results are stunning. Pretty much large format IQ, resolution, tonality, and detail.

I'm pretty sure my Linhof Consultant when he sees these negatives will again say, "With negatives like these you don't need a 4x5."

In my data mining I have not found any results using Microphen. I think your testing with Acufine has possibilities.

I'll do some mining about D74, AKA A74, and RHS. Ideally if I can get the formula I can mix my own.

I missed a show on Diane Arbus that focused on her work in Washington Square Park and Central Park. She described Washington Square Park in the 60's and 70's as being divided into three: wino section; junkie section; and hard core bull dikes.

She says it was a terrifying place, but she forced herself to hang out there. She made some friends, and then asked to photograph them. This is how she began to shoot the marginalized people she is known for.

In the beginning she shot with a Leica, but then changed to Rollieflexes. To deal with only 12 exposures, Diane carried three Rollies in a knap sack.

I can tell you that I have lost many shots due to having to reload. Also carrying two medium format cameras slows you down. In the heat of shooting sometimes working two cameras can become a liability and can be confusing.

I'm really looking forward to shooting Linhof's with CINE's. The 53/4.5 Biogon is a 28mm FOV in 6x7, and know that a 28 Cron is my most used lens. 70mm will definitely advance my work and workflow. I figure a 160 ISO would allow me to exploit F11 as my sweet spot. I'll only use one camera at a time, but I will have firepower and be able to shoot 70mm like a Leica.

Cal

Similar threads

- Replies

- 8

- Views

- 534

- Replies

- 56

- Views

- 5K

- Replies

- 20

- Views

- 3K