Or the friction in the clutches is too low. You can bow the clutches a bit in the middle towards the ribbon. I did it with a screwdriver. Aki Asahi is too smooth. Worked on mine. This idea came from Brett.

Erik.

Hi Erik,

It's worked on the three Contax II models I have replaced ribbons in as well (Aki Asahi, also, for clarity). But I hasten to add, I was prompted to try it by the many helpful posts various RFF members have made on the subject over the last few years.

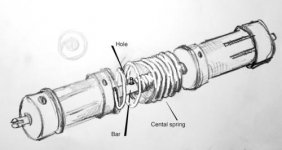

I think it does make sense, too, when one considers the way the mechanism is meant to function at the higher speeds. Putting aside the intermediate and slower speeds for a moment, the reason the Contax shutter works at all with just one set of ribbons, instead of the more usual pair per curtain, is because, at the higher speeds, the required slit width is pre-formed when the camera is wound. How much further the second curtain travels along the ribbons, relative to the first, is dependant on which speed is selected, of course. At the highest speed (1/1250 in the case of the II/III) the second curtain rests only marginally further than the leading edge of the first. At 1/500, as the camera is wound the second curtain travels a few millimetres further. And so on.

Now, the slit having been pre-formed, the beauty of the Contax design is that (when all is well, of course) the exposure will never taper across the gate. But in order for that to apply, the two curtains have to remain stationery, relative to each other, until the second curtain caps off the lower edge of the gate.

To me, it makes perfect sense, then, that, if the second curtain is capping off the exposure partway across the gate (or even completely), this is happening because it's running down the ribbons to meet the first curtain. If the correct fit exists between the ribbons and the clutches, there will be just enough interference to effectively, cause the first curtain, the second, and the ribbons to traverse the film gate as a single unit. Which is of course exactly what is meant to happen, at the fast speeds. Naturally there might also be other causes. Eg if the first curtain spring is broken or compromised it seems, at face value, to make sense that the second curtain would also gain on it. But we're assuming for the sake of this discussion that it's a Contax in basically serviceable order with nothing sinister making it malfunction, yes?

This is my understanding of it operation at the high speeds at least. But, like all of us, I am simply a Contax autodidact, and defer to the wisdom of members who have been fettling these cameras for far longer than myself!

😉

Cheers,

Brett