trittium

Well-known

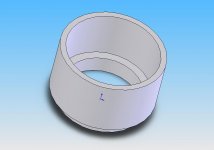

Hi Everyone, I am planning on putting some of my engineering skills to work and design an uncoupled adapter from arri to LTM. I was wondering if anyone knew or had access to detailed drawings (with measurements) of the mounting system. So far I have found that....

Thread is a m39 with 26 turns per inch

I have all the information for the arri lens, but not for the leica

Any help would be greatly appreciated.

I got this idea from an online auction. I am currently in collage, but will be graduating school soon. I would like to finish this quick while I have the machining resources available.

Thread is a m39 with 26 turns per inch

I have all the information for the arri lens, but not for the leica

Any help would be greatly appreciated.

I got this idea from an online auction. I am currently in collage, but will be graduating school soon. I would like to finish this quick while I have the machining resources available.