danieldumanescu

Member

Introduction

I have just finished overhauling my “new” Olympus 35 SP. I picked it up in Munich in January, from the “scrap” area of a big photo store, for 10 euro. No case, no strap, no lens cap, but the lens was clean, the overall condition reasonable and it fired on all speeds, although it was quite obvious it was slow. A low-to-medium amount of dust was gently covering it. An alkaline PX625A battery was inserted.

I didn’t pick it up just due to the price – it was a camera I was actually after and did not expect to get one so cheap. Of course, at the expense of my work, described below.

First of all, even if it may seem superfluous to the normal common sense, I do feel the need to point out that any attempt of performing these operations on your much beloved SPs are completely at your own risk! It’s a camera with a level of mechanical complexity way above average and it is extremely easy to lose, mis-assemble and destroy small but vital components. All the procedure was carried out according to my way of assessing things – there was no service manual implied. You’re free to say I was wrong on some points – pertinent and reasonable observations and corrections are welcomed. Bottom line, you have been officially warned!

Second, even if I shouldn’t mention this, I can’t help not doing it: please make sure to use proper tools. Screwdrivers that don’t properly fit the screw heads are shortcut to a world of anger, irreversible destruction and frustration. Also, during reassembly, do not tighten the screws using the same force you use for the ones designed to fix heavy objects on your walls. Once you’ve ruined a 0.7 mm thread I don’t have any miraculous solutions for you. A simple digital camera with macro capabilities will do wonders: take photos of all steps and before removing anything. Don’t rely just on my photos. Of course I posted here less than a third of all of them. It would have been impractical to put them all. And please don’t ask me to post more photos – I’ve no idea when time will allow me to do that.

My sincere thanks to Brian Legge, whose tutorial here on rangefinderforum has helped me a lot. I hope mine will be of at least as much help for others. Since Brian has described the major disassembly of the lens assembly from the camera body, I see no point in repeating this in my own words – I couldn’t explain it better. I will however point some constructive differences between his camera and mine and give you an alternate way of separating the lens itself from its base.

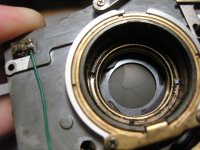

Brian, if you see this, you’ll also find the answer for your loose green wire 🙂

Let’s go on then!

I have just finished overhauling my “new” Olympus 35 SP. I picked it up in Munich in January, from the “scrap” area of a big photo store, for 10 euro. No case, no strap, no lens cap, but the lens was clean, the overall condition reasonable and it fired on all speeds, although it was quite obvious it was slow. A low-to-medium amount of dust was gently covering it. An alkaline PX625A battery was inserted.

I didn’t pick it up just due to the price – it was a camera I was actually after and did not expect to get one so cheap. Of course, at the expense of my work, described below.

First of all, even if it may seem superfluous to the normal common sense, I do feel the need to point out that any attempt of performing these operations on your much beloved SPs are completely at your own risk! It’s a camera with a level of mechanical complexity way above average and it is extremely easy to lose, mis-assemble and destroy small but vital components. All the procedure was carried out according to my way of assessing things – there was no service manual implied. You’re free to say I was wrong on some points – pertinent and reasonable observations and corrections are welcomed. Bottom line, you have been officially warned!

Second, even if I shouldn’t mention this, I can’t help not doing it: please make sure to use proper tools. Screwdrivers that don’t properly fit the screw heads are shortcut to a world of anger, irreversible destruction and frustration. Also, during reassembly, do not tighten the screws using the same force you use for the ones designed to fix heavy objects on your walls. Once you’ve ruined a 0.7 mm thread I don’t have any miraculous solutions for you. A simple digital camera with macro capabilities will do wonders: take photos of all steps and before removing anything. Don’t rely just on my photos. Of course I posted here less than a third of all of them. It would have been impractical to put them all. And please don’t ask me to post more photos – I’ve no idea when time will allow me to do that.

My sincere thanks to Brian Legge, whose tutorial here on rangefinderforum has helped me a lot. I hope mine will be of at least as much help for others. Since Brian has described the major disassembly of the lens assembly from the camera body, I see no point in repeating this in my own words – I couldn’t explain it better. I will however point some constructive differences between his camera and mine and give you an alternate way of separating the lens itself from its base.

Brian, if you see this, you’ll also find the answer for your loose green wire 🙂

Let’s go on then!