In order to get the bayonet cover off the flash locking lever must be removed from the end of the terminal. This has a blind screw with two small notches set into it for a pin spanner and undoes anti clockwise as usual. (There was a photo of the very similar part fitted to the Tele in a couple of the photos earlier in this thread—the Tele PC socket being fitted to the right, as you look at the front, instead of the left—as on the Cord.)

It’s possible, of course, to modify a screwdriver, socket or other hand tool to fit the notches in the screw. However even the best fitting tool can easily make small marks on this very visible fastener. How then, can it be removed without damage?

My approach is to simple but effective. I utilise a piece of old inner tube cut down to a small size, and apply friction to the fastener via the rubber. It’s possible to apply a surprising amount of force to smaller fasteners this way, either using your own digits, or perhaps via a flat surface when the fastener is attached to a larger assembly, such as a camera body. The beauty of using a clean piece of rubber is that it will impart absolutely no damage at all to a part, keeping it looking—dare I say it—mint.

The small knurled knob on the end of the cocking lever also has to be removed in order to slide the cocking/release lever out of the slot in the bottom of the bayonet cover. I tend to use a small pair of pliers or vice grips to carefully grip the knob without marking the knob excessively. A pair of tweezers or jewellers screwdriver can be used to fix the small screw behind the lever that helps retain the knob as you unscrew the knob.

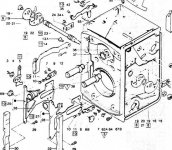

Having gently peeled back the leatherette around the corners with a suitable tool, and removed the four fixing screws for what I call the bayonet plate—it includes the bayonet rings for filters, hoods etc—after detaching the plate the Rolleicord will look like this:

You can see that the leatherette is still mostly attached to the bayonet plate, as it’s not usually necessary to completely remove it, making it just a little easier to align it neatly for glueing on reassembly. Looking at the front of the camera you’ll see the small threads for the fixing screws of the plate near the corners.

All the control levers for: shutter; aperture; double exposure selection and; self-timer lever/flash synch selection, where applicable—this Vb is “X” sync only—easily disconnect from their counterparts connected to the shutter assembly proper. Visible in the above shot at about 2 o’clock on the side of the shutter housing is the actuating arm for setting the aperture, which is driven by the fork on the end of the external control lever. The shutter speed is adjusted by rotating the serrated ring around the outside diameter of the shutter front, via a pin on the inside end of the external shutter speed selection lever. As you lift the cover clear of the shutter/viewing len,s these external levers detach and remain with the bayonet cover. The cocking and release lever stays with the shutter assembly, not the cover.

(Re-assembly of this is simply a matter of ensuring the external actuating levers are set to the same state as those on the camera proper so that they engage correctly. Ensure all pairs are set to, Eg. Bulb/f3.5 or 1/500/f22; double exposure; M sync; etc. and, by carefully introducing the cover, it will snap into its seat when aligned without play—you will know when it’s correct, and when it's not, by how it feels—don't force it, of course.)

Previously the taking lens has been unscrewed from the shutter assembly (they are not generally very tight and usually easily removed with thumb and fingers).

As the previous image shows, if access to the shutter blades or shutter escapements is all that is required this may be the extent of disassembly needed to the camera front. The black retaining ring that fastens the front of the Compur shutter assembly can be seen on the inside diameter of the shutter. The small (around a millimetre) screw that locks the retaining ring to the shutter has previously been removed above.

On the subject of the fastening ring: it does not have to be particularly tight, and in fact, often unscrews with the aid of a thumbnail. Shutter or aperture control levers that are excessively stiff to adjust might well be symptomatic of an inept assembler fastening the retaining ring too tightly, as excessive tension will have immediate and noticeable impact on the “feel” of the setting levers.

OK. In the following image we’re starting to get a bit deeper inside a Rolleicord.

For completeness the front group of the 75mm f/3.5 Xenar taking lens can be seen on the right. Having removed the black shutter retaining ring (top left next to the camera body) the setting ring, speed cam and front plate can also be seen above the bayonet plate. The speed cam ring is the one with the various slots machined into it, that engage the pins on the escapements in different combinations in order to regulate the range of shutter speeds possible (Bulb, to 1/500, in this case).

Still mounted around the inner shutter housing is its cocking rack (meshed to the gear pinion for the mainspring at around nine o’clock). This partly obscures the speed escapement, (the train of gears in the housing at 11-12 o’clock inside the shutter). Of course, this is frequently the heart of your problems if your Rolleis slow speeds begin to stutter or stick open. The components are small in size, indeed, and small amounts of old, evaporated organic lube the factory originally used will see the plot grind to a halt.

Indeed, if the shutter functions correctly at other speeds cleaning the star wheel and pallet (not visible above, located inside the escapement near the inner housing) with a single drop of lighter fluid and exercising the shutter for a while may be all that is required to get the slow speeds springing back into life. Repeat once, or twice, perhaps, until smooth running is maintained. A speck of Moebius synthetic watch oil on the pallet will prevent further problems recurring for years to come.

I’ll start a new post for the focus mechanism and all its quirks—still working on that one, coming up soon (promise!).

Cheers

Brett