FallisPhoto

Veteran

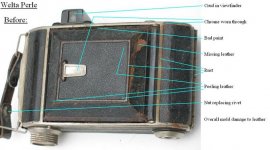

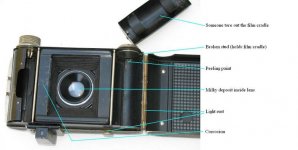

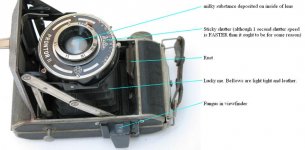

I am almost finished with the Welta Perle I am restoring and have taken photos of the process. However, one thing remains to do: At some point in the past, a former owner ripped the film cradle out of one end of it (the supply side). He broke off both studs that hold it in place. The cradle is a fairly tight fit for a roll of 120 film and I don't think I can use screws, because the heads would scrape against the ends of the spool. I'm thinking of grinding the heads of a pair of brads down, paper thin, and then either using epoxy or solder to install them as studs. The brads would be cut down to about 1/16 inch and should work. It would be a lot easier to do it with epoxy. Do you guys think epoxy would be strong enough or should I bite the bullet and get out the soldering iron?