Nokton48

Veteran

Dawes Cypress Wet by Nokton48, on Flickr

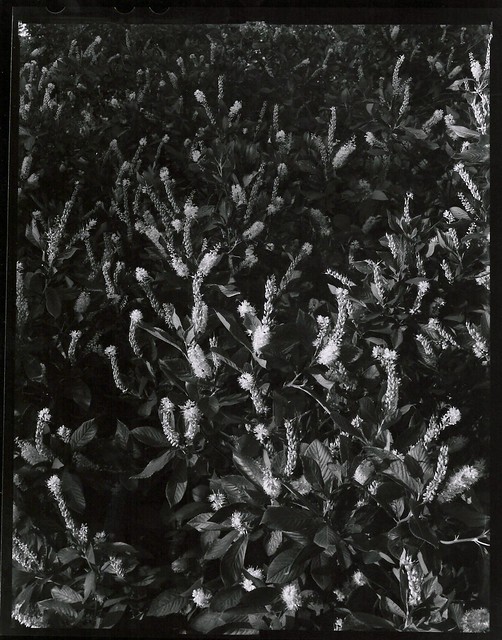

Dawes Cypress Wet by Nokton48, on Flickr Dawes Floral by Nokton48, on Flickr

Dawes Floral by Nokton48, on FlickrSinar Norma 4x5, 8x10 RC Aristo #2, Multigrade dev

Dawes Cypress Wet by Nokton48, on Flickr

Dawes Cypress Wet by Nokton48, on Flickr Dawes Floral by Nokton48, on Flickr

Dawes Floral by Nokton48, on Flickr Printing with new E3 by Nokton48, on Flickr

Printing with new E3 by Nokton48, on Flickr 5x7 E3 LED test 1 Norma TMX100 PMK+ by Nokton48, on Flickr

5x7 E3 LED test 1 Norma TMX100 PMK+ by Nokton48, on Flickr 5x7 E3 LED test 2 Norma TMX100 D76 by Nokton48, on Flickr

5x7 E3 LED test 2 Norma TMX100 D76 by Nokton48, on Flickr Rock Bridge E3 180mm Arista #2 58 Grandagon Norma by Nokton48, on Flickr

Rock Bridge E3 180mm Arista #2 58 Grandagon Norma by Nokton48, on Flickr Rock Bridge #2 E3 Arista #2 RC 58mm Grandagon Norma by Nokton48, on Flickr

Rock Bridge #2 E3 Arista #2 RC 58mm Grandagon Norma by Nokton48, on Flickr Darkroom Sink Finally Plumbed 2 by Nokton48, on Flickr

Darkroom Sink Finally Plumbed 2 by Nokton48, on Flickr 8x10 Norma 480 Apo Ronar by Nokton48, on Flickr

8x10 Norma 480 Apo Ronar by Nokton48, on Flickr Reprint DII Rock Bridge 1 by Nokton48, on Flickr

Reprint DII Rock Bridge 1 by Nokton48, on Flickr Reprint DII Rock Bridge 2 by Nokton48, on Flickr

Reprint DII Rock Bridge 2 by Nokton48, on Flickr Reprint DII Rock Bridge 3 by Nokton48, on Flickr

Reprint DII Rock Bridge 3 by Nokton48, on Flickr Reprint DII Rock Bridge 4 by Nokton48, on Flickr

Reprint DII Rock Bridge 4 by Nokton48, on Flickr Reprint DII Rock Bridge 5 by Nokton48, on Flickr

Reprint DII Rock Bridge 5 by Nokton48, on Flickr Eagle Drain Tubs by Nokton48, on Flickr

Eagle Drain Tubs by Nokton48, on Flickr Poor Mans JOBO Film Processor by Nokton48, on Flickr

Poor Mans JOBO Film Processor by Nokton48, on FlickrHey Dan-

I remember reading someplace that Federal had a problem with a center "hot spot" with their model 450 4 x 5 diffusion enlarger. They solved it by sandblasting the center and "feathering" it out towards the edges of the diffusion ground glass.

Completed E3 5x7 Glass Carrier by Nokton48, on Flickr

Completed E3 5x7 Glass Carrier by Nokton48, on Flickr How not to ship AN Glass overseas by Nokton48, on Flickr

How not to ship AN Glass overseas by Nokton48, on Flickr