gdi

Veteran

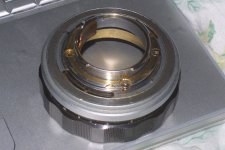

I am converting a 0.95 and need to know how far down to trim the rear element shroud. It would seem to make sense to just trim the little tabs off and it should not foul a M8 or RD-1. But I want to be sure.

Would someone with a converted lens mind taking some shots of the rear with the lens focused at infinty (all the way out). It would really help!

Thanks!

Would someone with a converted lens mind taking some shots of the rear with the lens focused at infinty (all the way out). It would really help!

Thanks!