RicardoD

Well-known

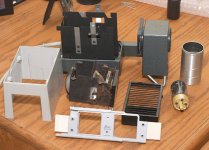

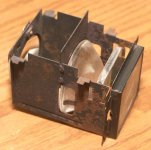

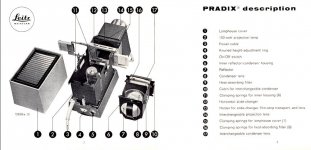

As part of my dive into this Rangefinder business I picked up a working Leitz Pradix 150w slide projector. It just arrived in the mail today but I am in love with the thing already. It's just a small simple manual mechanical device to project slides. A very simple 2 slide changer that you slide back and forth, when one slide is being projected, you can reload the other.

I just ordered an original owner's manual for it from Pacific Rim Camera for $10.

Thankfully it was shipped to me as found by the previous owner untouched... meaning original cobwebs, grime and all are still intact (i.e. no damage by unnecessary cleaning).

I need to do a CLA on this thing. The 85mm Elmaron lens is filthy and the metal chassis which holds the light collector lens has surface rust on it. I want to take it apart, restore the chassis, clean the multiple lens, lubricate the lens barrel and slide holder mechanism and then put it back together. But I want to do it right and I want to do it myself. Some questions:

1)What is the proper way to clean the lens? And light collector?

2)What is the proper lubricant for the lens to lens barrel focus, you can see the spiral groove has dried out lube?

3)Proper way to clean the first surface parabolic mirror behind the bulb.

4)And I need to get rid of some of the surface rust on inner mirror chassis and possibly repaint this inner chassis. Outside body is fine.

Any advice would be appreciated.

I just ordered an original owner's manual for it from Pacific Rim Camera for $10.

Thankfully it was shipped to me as found by the previous owner untouched... meaning original cobwebs, grime and all are still intact (i.e. no damage by unnecessary cleaning).

I need to do a CLA on this thing. The 85mm Elmaron lens is filthy and the metal chassis which holds the light collector lens has surface rust on it. I want to take it apart, restore the chassis, clean the multiple lens, lubricate the lens barrel and slide holder mechanism and then put it back together. But I want to do it right and I want to do it myself. Some questions:

1)What is the proper way to clean the lens? And light collector?

2)What is the proper lubricant for the lens to lens barrel focus, you can see the spiral groove has dried out lube?

3)Proper way to clean the first surface parabolic mirror behind the bulb.

4)And I need to get rid of some of the surface rust on inner mirror chassis and possibly repaint this inner chassis. Outside body is fine.

Any advice would be appreciated.