While I like David's far more personal story involving Bill Collings better than mine, I do feel fortunate to have one of my own to share. I first met Bill back in 1991 after leaving my job in Dallas and moving to Austin. Other than the fact that I no longer desired a career in engineering I had no clue what I wanted to do. Fortunately I had saved up a fair amount of money and had some time to figure it out. I thought it would be cool to build acoustic guitars and was hoping to land a job with Bill. So even though I had absolutely no woodworking skills (but I do love guitars) I just showed up at his shop offering him two weeks of my time for free as sort of a trial period.

As I mentioned over in the Putts thread, Bill was so busy at that point that he couldn't take me up on my offer — he simply didn't have the time to show me what it was that he could us my help with. Bill did take the time to show me around his shop along with a few of his guitars. He was also kind enough to lend me a few of his books on guitar building that he kept around. To my surprise I did eventually receive a job offer some time later. Collings Guitars was growing and had relocated to a larger facility outside of Austin (the one that David mentioned). By then I had already started a new career in marketing communications and was actually enjoying my work. So (hangs head) I turned down the chance to work at Collings Guitars.

The small nest egg that I had arrived in Austin with didn't last forever but by 1995 I had managed to save up enough money to be able to buy a Collings guitar for myself. I had also turned a friend of mine (a far, far better player than myself) on to Bill's guitars. Eventually we each ended up having a guitar custom made for us. It was somewhat unfortunate that I had become enamored with rosewood at that time as I would later discover that I am a mahogany guy at heart so that guitar is no longer with me. I'm saddened just a bit by that fact for the first time ever as I look back at these images. (It has been well over twenty years since I last viewed the slides that I made these scans from.) It had gotten to the point where the guitar just wasn't being played. Realizing just how much work actually goes into building a guitar that seemed like a real shame. In 2012 I ended up trading it to someone that would play it and appreciate it.

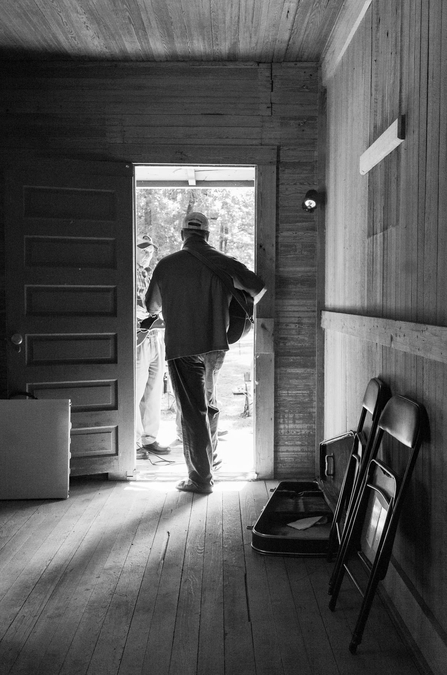

Anyway, when my buddy and I were having our guitars built the crew out at Collings were great. The allowed us stop by often to check in on the guitars as they evolved over time through the various stages of the build and answered a nearly endless amount of questions. My friend and I took photos of each other to document the experience. Sadly I have just a handful of images. My apologies as I rushed the scanning of the slides just so I could share here. But they at least they do contain "guitar content" and provide a tiny glimpse into the state of Collings guitars circa 1995. While I did then, and still do, find it all to be very fascinating, looking at myself in these photos it strikes me that this all took place much longer ago than I realized. Time flies as they say. With that in mind, David, please feel free to correct me if I bungle any the details pertaining to the work involved.

These are matched sets of sides that are waiting for the next phase of the build process. Here they already have the side braces along with the kerfing glued up. The kerfing provides greater support at the point where the top and back of the be attached to the sides. Here you can see that the guitar-to-be serial number has already been affixed. They also mark the top, back, neck, etc. with the same serial number so that all of the pre-chosen components can be easily identified for assembly. (My guitar was to be serial number 2051.)

We got to pick out the wood blanks to be used in the construction of the guitars. Here is the top of the guitar with the set of spruce that I chose. Just as the sides match, so too do the top and back of the guitar that are made up of a piece of wood that has been split in half and bookmatched — after the quartersawn wood is split in half it is opened up like a book before being glued together to form a single piece. As seen in this photo mine was to be an OM guitar, the same sized body as used in a 000 guitar. My buddy had a larger dreadnaught sized guitar made for him.

This is rosewood back for the guitar. Here you can see the bookmatched effect where the grain on each side of the split piece of wood mirrors that of the other. The two pieces are separated by a lighter strip of purfling (made up of very small pieces of wood set in a decorative pattern).

Here is the flip-side of the back of the guitar. The bracing pieces have already been attached with glue. As with the top of the guitar, the braces will be carved before the body of the guitar is fully assembled. This is part of what gives the guitar it's voice.

Lastly, this image is from a later visit to the shop. Here you can see the body of my guitar resting on it's side after the assembly of the pieces appearing in the previous photos has been completed. Soon the neck of the guitar will be attached to the body.

Sorry for the extremely lengthy post. Obviously photography gear isn't the only thing that people can geek out over.