The anticipation is killing me 😉

How is it going?

You must have tackled at least 10 problems, and of course got some new ones in return.

It's going pretty well, but no major news to report as of yet. As usual the final parts order is taking up much of my time, and once it's out of the way I'll write up a schedule / timeline that should be significantly more reliable than my earlier projections. Then I'll be able to move on from the mechanical stuff and focus on electronics, programming and testing.

Long story short, I'm doing this final parts order in stages. The first stage is to make prototypes of each module that are bulky and ugly, but perfectly functional and infinitely adjustable. Once adjustments have been made to account for any deviations between the theoretical and the ideal positions of things, such as lens elements for Kohler alignment in the light source, measurements will be made. Then the design will be updated, another order will be made, and hopefully then we will be totally done with these parts. (but only this first stage will be needed to make the first test scan!)

Just so you know, the blue parts of the diagram will need to be able to make three passes of the length of the scanner each second at maximum speed. At that rate, it's extremely important to carefully position the center of mass of each moving part, while still keeping things small and lightweight, and at the same time minimising aerodynamic effects caused by this fast motion, and avoiding wobbling, etc etc. Anyway I've got a design that can get around all these constraints, I just need the measurements from the first stage of this parts order.

I'll make an update here of when the order for that first set of parts has been submitted, as this order seems to defy any sort of forecast schedule. However earlier on today I finished what I consider to be the hardest module, the light source.

Regarding suggestions made recently:

Sound absorbing pad - looks good! That link is a material that has the right properties.

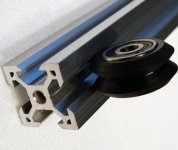

Avoiding belt - that's what I did in the first prototype last year, using a screw linear motion thing, and it was a bit too slow. If the off-the-shelf belt needs to be replaced by the user each year or so in a worst case heavy-usage scenario, I think that's acceptable for the speed advantages it brings. However if the belt is especially problematic I will spend more time investigating screws and racks.

Super accurate measurement cart - interesting! Intuitively my response would be to say that having the stepper motor moving along with the optical modules would add excessive inertia, which would be bad, but earlier on in the week I was playing around with some very lightweight drone motors, so this is a possibility. However I'm going to stick with the current approach for the prototype, but I'll keep this in mind.

Floppy belt - That does sound inconvenient, but as it is the wheels which keep the image plane perpendicular to the lens axis, even in a worst case scenario all that would happen is that the 'tiles' have less regular gaps than normal, which means that the software tile stitching would take several milliseconds longer than before. I don't think this is too much of a worry, but I'll keep an eye out for possible expansion and sagging of the belt, which is something that should be minimised in any case.

Tension tolerant ball bearings - I actually didn't know this, thanks for making me realise that not all ball bearing assemblies are the same. Fortunately I lucked out, and the bearings I have now are designed for high tension loads, but when I make other orders for bearings in the future I'll make sure to be aware of whether they can deal with the tension properly.